China PVDF Coated Aluminium Coils Manufacturer | RAYIWELL

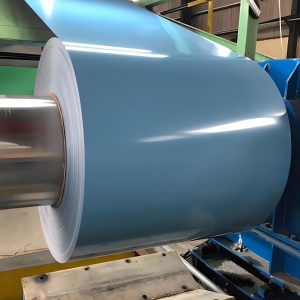

Color coated aluminium coils, as the name suggests, are painted on the surface of aluminum substrates. Commonly used are fluorocarbon color-coated aluminum coils and polyester color-coated aluminum coils. They are widely used in aluminum-plastic panels, industrial factory roofs and walls, and aluminum louvers. , composite panels, aluminum ceilings, cans, electronic products.

PVDF colored aluminum and PE colored aluminum are common colored aluminum materials. They have certain differences in properties, applications and service life.

PVDF colored aluminum is a colored aluminum material based on polyvinylidene fluoride (PVDF). It has the following characteristics:

Strong corrosion resistance: PVDF colored aluminum has good corrosion resistance and can resist the erosion of chemicals such as acids and alkalis. It is suitable for making chemical equipment, pipes, containers, etc.

High mechanical strength: PVDF colored aluminum has high mechanical strength and hardness, can withstand greater pressure and impact, and is suitable for making mechanical parts, tools, etc.

Good high temperature resistance: PVDF colored aluminum has good high temperature resistance and can remain stable in high temperature environments. It is suitable for making kitchen utensils, ovens, etc. Suitable for occasions that need to withstand greater pressure, impact and high temperature.

PE colored aluminum is a colored aluminum material based on polyethylene (PE). It has the following characteristics:

Light weight: PE color aluminum has a low density and the product is light in weight, making it suitable for making lightweight and portable products.

Lower price: Compared with PVDF colored aluminum, PE colored aluminum is cheaper and suitable for occasions where costs need to be controlled.

Compared with PVDF colored aluminum, PE colored aluminum has the characteristics of light weight, good flexibility, and lower price, and is suitable for products that need to be lightweight and flexible. At the same time, PE colored aluminum also has good corrosion resistance and high temperature resistance, but it is slightly inferior to PVDF colored aluminum.

PVDF coated aluminium Coils

| Aluminum Alloy | AA1100; AA3003; AA5005 |

| Coil thickness | 0.25mm,0.30mm,0.40mm,0.50mm |

| Coil width | 1240mm, 1270mm, 1520mm, 1550mm, 1575mm |

| Coating thickness | Over 25 micro |

| Diameter | 405mm, 505mm |

| Coil weight | 2.5 to 3.0 tons per coil |

| Color | White series, metallic series, Dark series, Gold series( accept color customs) |

Polyester coated aluminium coils

| Aluminum Alloy | AA1100; AA3003; AA5005 |

| Coil thickness | 0.18mm,0.21mm,0.25mm,0.30mm,0.40mm,0.45mm,0.50mm |

| Coil width | 1240mm, 1270mm, 1520mm, |

| Coating thickness | Over 16 micro |

| Diameter | 405mm, 505mm |

| Coil weight | 2.5 to 3.0 tons per coil |

| Color | White series, metallic series, Dark series, Gold series( accept color customs) |

Are PVDF Coated Aluminium Coils Suitable for Interior and Exterior Applications?

PVDF coated aluminium coils are suitable for both interior and exterior applications.

PVDF (polyvinylidene fluoride) is a highly durable and weather-resistant coating that provides excellent protection against UV rays, corrosion, and fading. This makes it suitable for use in various environments, including both indoor and outdoor settings.

PVDF coated aluminium coils are commonly used in the construction industry for applications such as wall cladding, roofing, facades, and signage.