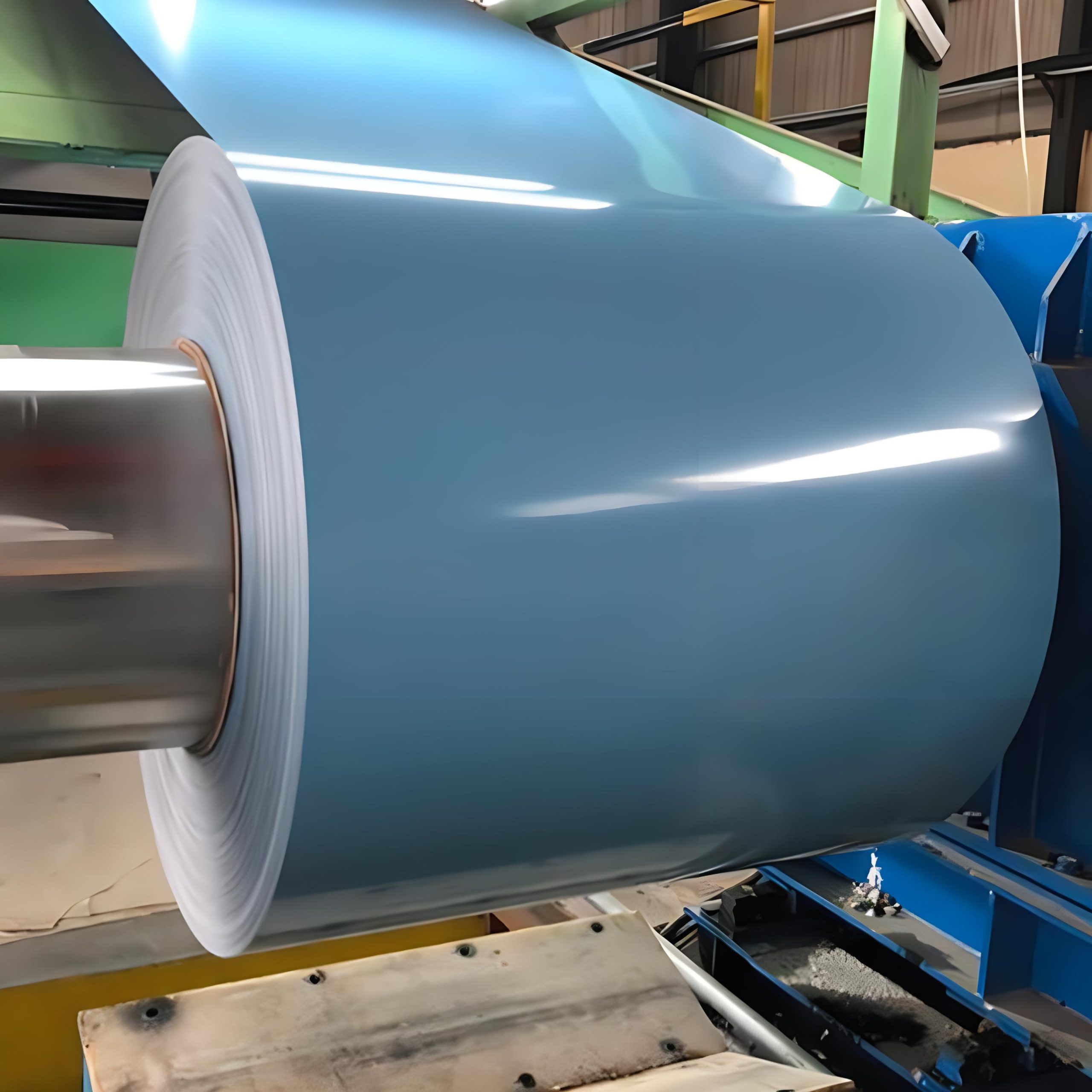

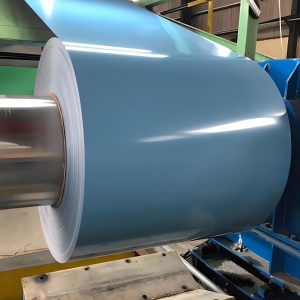

China 3105 color coated aluminium coil Manufacturer

Color coated aluminium coil is a rolled material made of high-quality aluminum alloy material. Its surface is coated and can show various colors and textures.

Color coated aluminium coils have the characteristics of light weight, high strength, corrosion resistance, easy processing, and easy maintenance, and are widely used in construction, decoration, automobile manufacturing and other fields.

The coating materials of color-coated aluminum coils can be selected according to different needs, such as fluorocarbon resin, polyester resin, etc.

These coating materials have good adhesion and UV resistance, which can ensure that the color-coated aluminum coils maintain their appearance and stable performance during use.

Color coated aluminium coils have a wide range of uses. In the construction field, they can be used to make various decorative panels, curtain wall panels, roofing materials, etc.

In the automotive field, they can be used to make body panels, doors and other components. In the electronic product field, they can be used to make various shells and Cover plate

PVDF Color coated aluminium coil

| Aluminum Alloy | AA1100; AA3003; AA3105, AA5005 |

| Coil thickness | 0.25mm,0.30mm,0.40mm,0.50mm |

| Coil width | 1240mm, 1270mm, 1520mm, 1550mm, 1575mm |

| Coating thickness | Over 25 micro |

| Diameter | 405mm, 505mm |

| Coil weight | 2.5 to 3.0 tons per coil |

| Color | White series, metallic series, Dark series, Gold series( accept color customs) |

Polyester(PE) color coated aluminium coil

| Aluminum Alloy | AA1100; AA3003; AA3105, AA5005 |

| Coil thickness | 0.18mm,0.21mm,0.25mm,0.30mm,0.40mm,0.45mm,0.50mm |

| Coil width | 1240mm, 1270mm, 1520mm, |

| Coating thickness | Over 16 micro |

| Diameter | 405mm, 505mm |

| Coil weight | 2.5 to 3.0 tons per coil |

| Color | White series, metallic series, Dark series, Gold series( accept color customs) |

The application of colored aluminum coils in the packaging industry is gradually increasing, especially in the field of food packaging.

Because colored aluminum coils have excellent wear resistance, moisture resistance, and barrier properties, they can effectively protect food from the external environment and extend the shelf life of food.

As consumers increasingly pay attention to food safety and packaging aesthetics, the application of colored aluminum coils in the packaging industry is expected to further expand

As a lightweight, high-strength, corrosion-resistant material, colored aluminum coils are suitable for the manufacture of solar panel brackets.

Its excellent electrical conductivity and good appearance also meet the high standards of solar panel brackets.

What are the environmental advantages of colored aluminum coils?

Colored aluminium coils have the following advantages in terms of environmental protection:

Recyclability: Colored aluminum coil is a recyclable material with a recycling rate of more than 80%, which effectively reduces the generation of waste and is conducive to resource recycling.

Energy saving: The thermal conductivity of colored aluminum coils is high, which can effectively reduce energy consumption and carbon emissions, and meets the requirements of energy conservation and emission reduction.

Non-toxic and harmless: Colored aluminum coils do not contain formaldehyde, benzene and other harmful substances and gases, and do not release radioactive substances. They are a non-toxic and environmentally friendly product.

Reduce environmental pollution: Because colored aluminum coils can be recycled and reused, environmental pollution by waste is avoided.

At the same time, during the production and processing process, the waste materials and wastewater generated by the colored aluminum coils are also effectively treated and discharged, reducing environmental pollution.

Corrosion resistance: Colored aluminum coils have good corrosion resistance and are not easily oxidized and corroded, reducing the frequency of maintenance and replacement, thereby reducing the impact on the environment