China 1100 Color coated aluminum coil Manufacturer RAYIWELL

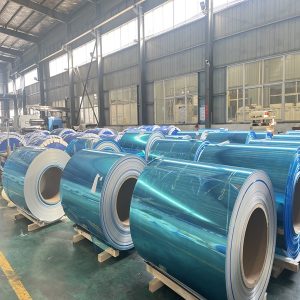

Color coated aluminum coil are the surface coating and coloring treatment of aluminum plates or aluminum coils.

The commonly coated aluminum coils are fluorocarbon color-coated aluminum coils and polyester color-coated aluminum coils.

Color coated Aluminum coil means the coil is processed with surface coating of PE, HDPE, PVDF, FEVE Paints.

Color coated aluminum coil are Widely used for building industry, like Aluminium Roofing, Ceiling, Wall Cladding, Composite Panel, etc.

Advantages of color coated aluminum Coil

Stable Property, Anti-corrosion, Solvent Resistance, UV Rays & Severe Weather Resistance, 15 Years Warranty, etc.

Specification of color coated aluminum coil

| Product | Color Coated Aluminum Coil / Aluminium sheet |

| Alloy | AA1100, AA3003, AA3003, AA3105 or custom |

| Temper | H14, H24, H26, H44 |

| Thickness | 0.25-1.5MM |

| Width | 100-2000MM |

| Color | All Ral Colors |

| Coating | PE, HDPE, PVDF, FEVE, NANO |

| Coating Thickness | 5-65um, Customized |

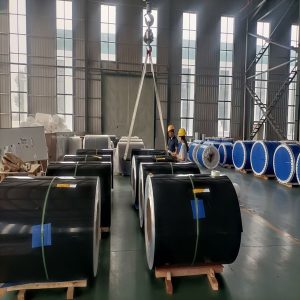

| Package | Eye to wall, Eye to Sky, wooden pallet |

| Warranty | 5-15 years. |

How to manufacture color coated aluminum coil?

The manufacturing process of coated aluminum coil involves several steps to ensure the production of high-quality and durable coils. Here is a breakdown of the process:

1. Coil Preparation: The process starts with the preparation of aluminum coils. The coils are carefully inspected for any defects or imperfections. They are then cleaned and treated to remove any dirt, oil, or oxidation present on the surface.

2. Surface Treatment: The next step is surface treatment, which involves applying a chemical treatment to the aluminum coils. This treatment helps enhance the adhesion of the coating and improves the overall durability of the finished product. Common surface treatments include chromate conversion coating or anodizing.

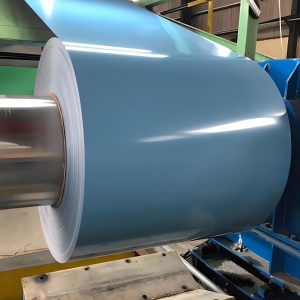

3. Coating Application: After surface treatment, the coils are coated with a layer of paint or coating material. This coating can be a liquid paint or a powder coating, depending on the desired finish and application. The coating is applied using various methods such as roll coating, spray coating, or coil coating.

4. Curing: Once the coating is applied, the coils are sent through a curing oven. The curing process involves subjecting the coated coils to high temperatures, typically around 200-250 degrees Celsius. This helps the coating material to chemically react and form a strong bond with the aluminum surface. The curing time can vary depending on the type of coating used.

5. Cooling and Inspection: After the curing process, the coils are cooled down to room temperature. They are then inspected for any defects or imperfections in the coating. This includes checking for adhesion, color consistency, and overall appearance.

6. Slitting and Packaging: The final step is slitting the coated aluminum coils into the desired width and length. This is done using specialized slitting machines. The coils are then packaged and prepared for shipping to customers.

Overall, the manufacturing process of coated aluminum coil involves careful preparation, surface treatment, coating application, curing, inspection, and packaging.

This ensures that the final product meets the required quality standards and is ready for use in various applications such as building facades, automotive parts, and electronic appliances.

Coil coating is an industrial process used to produce precoated aluminium coils. There are different types of coatings: anodizing, paint, liquid or powder coating. This method is used to promote the use of aluminium in the most environmental condition.

AYIWELL MFG LIMITED is aluminum sheet coils suppliers and also a manufacturer of other steel and aluminum materials like Aluminum strip, aluminum coils, aluminum plate, aluminum checkered plate and carbon steel plate.

RAYIWELL MFG LIMITED also sell cold rolled steel coils, SPCC, Galvanized steel sheet, SGCC, Galvalume steel coils, Aluzinc steel coils, pre-painted Galvanized steel coil, PPGI and we can sell Non Grain oriented steel or CRNGO and stainless steel sheet, stainless steel coil.