China Prepained aluminum coil Manufacturer and Supplier | Ruiyi

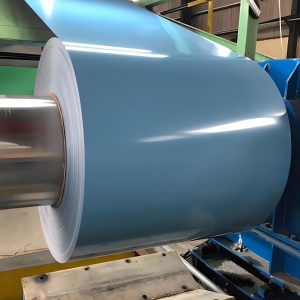

Color Coated Aluminium refers to the aluminum coil through coating and coloring treatment generally includes PE coated aluminum coil and PVDF coated aluminum coil.It has color coated aluminum coil, sheet and foil.

Color aluminum plate, you may think it will be very strange, but it can be seen everywhere in our life. Because of its diverse colors and delicate brushed texture, it is widely used in aluminum photo frames, boutique cabinets, signs, lighting, home appliances, handicrafts, architectural decoration, auto parts decoration, etc.

Color aluminum plate used in architectural decoration

With the development of society, more and more people like to apply the oxidized brushed aluminum plate to the decoration of buildings. Its unique metal texture makes the space more high-grade, atmospheric and beautiful. A variety of colors can be selected, and customized processing can also be selected to better meet individual needs. The oxidized brushed aluminum plate has excellent washing resistance, anti-static and dust-proof, easier to clean, and does not leave fingerprints after touching, which is very suitable for architectural decoration.

Color aluminum plate used in home appliance decoration

When the oxidized brushed aluminum plate is applied to home appliance decoration, it breaks the tranquility of traditional white home appliance decoration. The appearance has a soft metallic texture and delicate brushed texture, which enriches the visual effect of the product. Secondly, the oxidized brushed aluminum sheet material is healthy and environmentally friendly. The sheet has no paint, no PVC film, no smell, no glue, and the production process is environmentally friendly. The sheet can be recycled and recycled; it meets the needs of the country to promote the use of environmentally friendly materials.

Color aluminum plate used in auto parts decoration

In recent years, brushed aluminum sheet has been widely favored by automobile manufacturers as the base material for auto parts manufacturing. What are the advantages when the oxidized brushed aluminum sheet is applied to the interior decoration panel of the car? 1. It is more elegant and beautiful, and brings higher-grade visual enjoyment: 2. It is resistant to ultraviolet rays and does not fade, has excellent washing resistance, and is not easily eroded by cleaning agents; 3. The brushed texture can be customized, and the car style is changeable and diverse. The brushed aluminum plate can better cater to various car styles

Specification of Color Coated Aluminum

| Aluminum alloy: | 1050 1060 1100 3003 3004 3105 5052 5754 8011 |

| Thickness: | 0.016-5.0mm |

| Width: | <2650mm |

| Coils core diameter: | 150mm ,405mm, 505mm, 508mm, 510mm |

| Coating thickness: | PVDF >=25micron, POLYESTER>=18micron |

| Color standard: | E < 2 or it is not obvious by eyeballing |

| Pencil hardness: | > 2HB |

| Coating adhesive: | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

| T-Bend: | ≤2T |

| Boiling point: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

| Corrosive: | surface deep in the 5% muriatic acid and 5% NaCL, interior deep in the 2% muriatic acid and 2% NaCL, after 48 hours, no change |

| Coating Type | Durability |

| PE | about 5~10 years indoor |

| HDPE | 8~15 years indoor or outdoor |

| PVDF | 15-20 years indoor or outdoor |

| FEVE | more than 20 years indoor or outdoor |

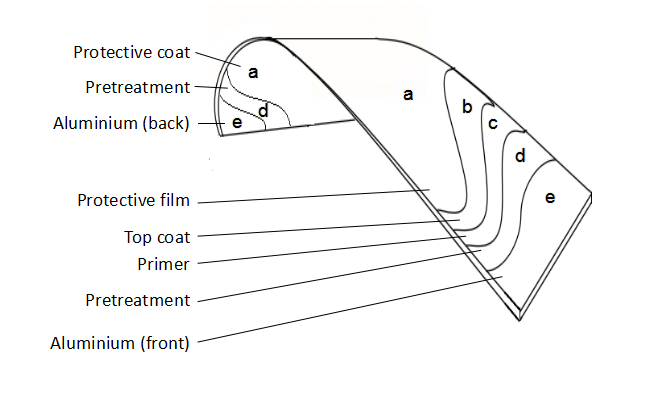

Features of color coated aluminum sheet:

1.Paint: 70/30 PVDF from high quality paint;

2.Pretreatment: the raw aluminum has to be washed by acid, and chromized. After it is dried out, it will be covered by oxide film to heighten the adhesion;

3. Colors: Various Colors, basis on RAL and PARTON, can be customized;

4. Coating:

Polyester ( PE) :

one layer, about 18μm;

two layers, 25~28μm.

Polyvinylidene Fluoride (PVDF ) :

two layers,at least 25μm;

Advantages of Color Coated Aluminum

- Low density, high hardness, weight per unit volume is the lightest of metal materials.

- Unmatched solidity, various colors and safe to use

- Uniform and bright color and strong adhesion

- Durable, acid and alkali resistant, corrosion resistant, weather resistant, resistant to decay, abrasion, UV resistant, weather resistant