China 1050 3003 5052 5754 PVDF PE Prepainted steel plate Color Coated Aluminum Coil For Building Outdoor Wall Panel Manufacturer and Supplier | Ruiyi

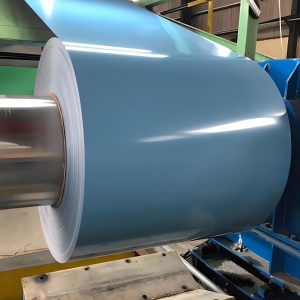

1050 3003 5052 5754 PVDF PE Prepainted steel plate Color Coated Aluminum Coil For Building Outdoor Wall Panel

Color coated aluminium coil has a rich color range, whether it is a residential residence, a large commercial network or a large-scale exhibition center, the color-coated aluminum coil can add color to it. Color coated aluminum coils have provided architects, designers and owners with a color space to achieve personalized exterior walls and ceilings, and it is also the most ideal material for architectural modeling.

Whether it is a multi-functional large building or a unique and creative new building, the color coated aluminum coil can always meet the different requirements of modern and classical architectural styles, and make the building colorful. Products are used in many fields such as electronic appliances, instruments, lighting, packaging, home improvement and so on

Color aluminum has the advantages of light texture, easy processing and forming and other benefits. So it is widely used. The aluminium coil curtain wall is one of the most widely use of the product. We can see the curtain wall every where in the large buildings and offices. It’s not just for aesthetics, also other performance like keep warm Soundproofing etc. Nowadays, many people prefer to use aluminum to produce curtain wall than steel and stainless. So they are competitive in the national market

There are two types of coated aluminum coil include PE and PVDF.

PE: The polyester coating formed by repeatedly baking the surface of the aluminum plate , then can form a continuous solid film. That is firmly attached and has protective and decorative properties.

PVDF: Fluorocarbon coatings mainly refer to coatings of vinylidene fluoride homopolymer or copolymers of vinylidene fluoride, and other small amounts of fluorine-containing vinyl monomers.

| Alloy | 1100 3003 5005 1050 1060 1070 3102 8011 3A21 3105 8079 |

| Aluminum thickness | 0.1mm-3mm |

| Aluminum max Width | 2200mm standard width: 1240mm special width such as 1300mm, 1520mm, 1570mm,1595mm are also available |

| Coil’s standard diameter | interior diameter: 150mm, 405mm, 505mm |

| Coating finish | PE, PVDF, PLOYESTER, ACRYLIC ACID |

| MOQ | 5 tons per size |

| Gloss | meet the customer’s requirement |

| Total coating thickness | PVDF coating: more than 25 microns |

| Coating adhesive | no lower than first grade |

| Impact resistance | no cracking and peeling (50kg/cm, ASTMD-2794:1993) |

| Outer packing | export standard, wooden pallet |

1. PE is generally used indoors. The other is generally used outdoors.

- PE has a warranty of 15-20 years. PVDF has a 10-year warranty.

- PE only has single coating and double coating. PVDF includes double coating and triple coating.

- PE is mostly used for coil. PVDF is mostly used for sheet.