-

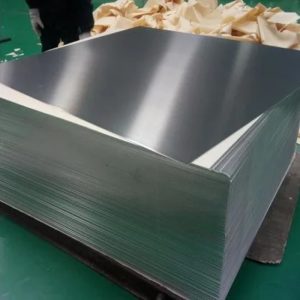

3003 Aluminum clad sheet

Aluminum clad sheets are widely used in architectural projects for building facades, curtain walls, roofing, and decorative elements due to their aesthetic appeal, durability, and weather resistance.

-

BIS Certified 50C600 CRNGO Silicon Steel

CRNGO (Cold Rolled Non-Grain Oriented) Silicon Steel Sheet is a type of electrical steel that is used in the production of transformers, motors, and other electrical equipment。

-

Galvanized Steel Grating

Galvanized steel grates are widely used in flooring, catwalk, mezzanine,decking, stair tread, fencing, ramp, dock, trench cover, drainage pit cover, maintenance platform, wash rack, ventilation screen, storage rack, window and machinery safe guards, workshop, motor rooms, trolley channel, heavy loading area, boiler equipment and heavy equipment area.

-

3105 8011 Ropp Cap Aluminium Sheet

Ropp Cap Aluminium Sheet is commonly used in the production of bottle caps, jar lids, and other types of closures for food and beverage containers.

-

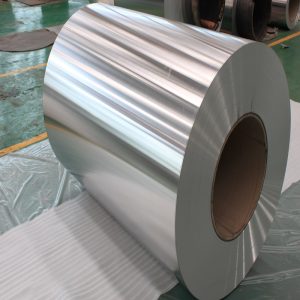

3105 8011 Aluminum Closure Sheet Coil

Aluminum closure sheet coil is commonly used in the production of bottle caps, jar lids, and other types of closures for food and beverage containers. It is highly corrosion-resistant, lightweight, and easy to work with, making it an ideal choice for packaging applications where a tight seal is required.

-

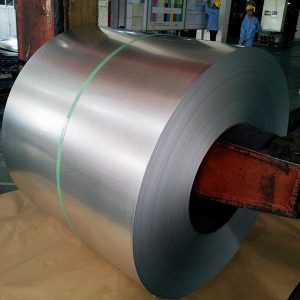

B35A300 Silicon Steel Sheet

Silicon steel contains 1.0-4.5% silicon and silicon alloy steel with a carbon content of less than 0.08% is called silicon steel.

It has the characteristics of high magnetic permeability, low coercivity, and large resistivity, so hysteresis loss and eddy current loss are small.

Mainly used as magnetic materials in motors, transformers, electrical appliances and electrical instruments.

-

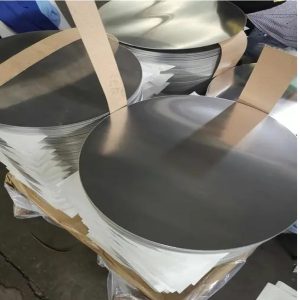

1050 1060 1100 aluminum circles

Aluminum circle, also known as aluminum round sheet, is a round-shaped aluminum product that is commonly used in various applications such as cookware, lighting fixtures, and signage.

-

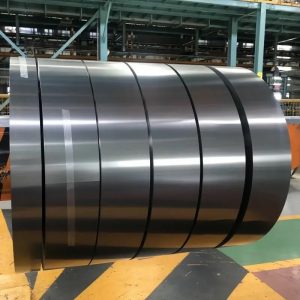

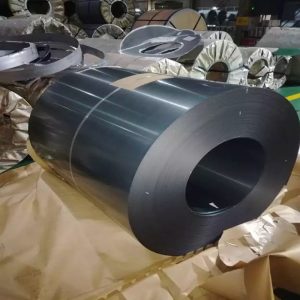

50W1300 Silicon Steel Strip Coil

Silicon steel contains 1.0-4.5% silicon and silicon alloy steel with a carbon content of less than 0.08% is called silicon steel.

It has the characteristics of high magnetic permeability, low coercivity, and large resistivity, so hysteresis loss and eddy current loss are small.

Mainly used as magnetic materials in motors, transformers, electrical appliances and electrical instruments。

-

Top 10 Aluminium Foil Manufacturer

Aluminium foil is a light, soft, moisture-proof, anti-corrosion, resistant to high and low temperatures, good thermal conductivity, and good sound insulation.

-

Aluminum Round Bar 2024 T3 7075 T651

2024 and 7075 aluminum round bar are both high-performance aluminum alloy materials with excellent mechanical properties, processing properties and corrosion resistance. They are widely used in aviation, aerospace, automobiles, machinery and other fields, and aluminum rods are these