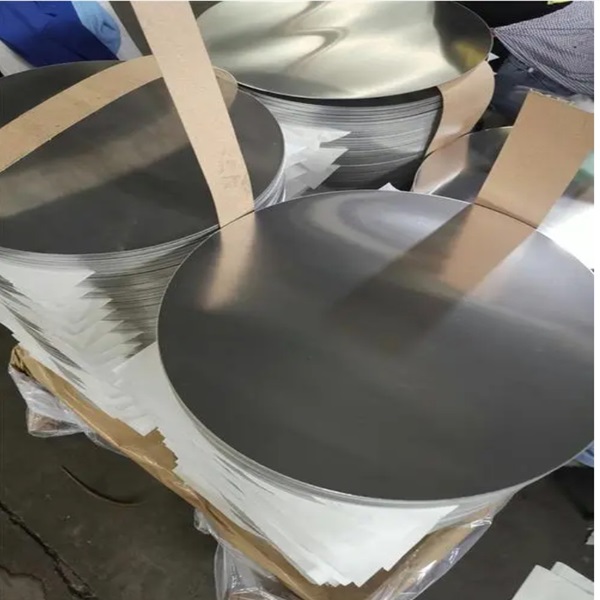

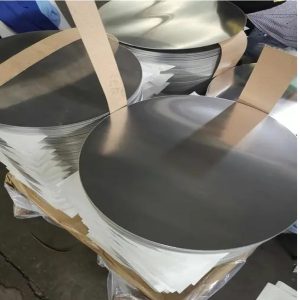

1050 1060 1100 aluminum circles Manufacturer and Supplier

Aluminum circles, also known as aluminum round sheets, are a round-shaped aluminum product that is commonly used in various applications such as cookware, lighting fixtures, and signage.

It is made by cutting a large aluminum sheet into a circular shape and is available in different thicknesses and diameters to suit different needs.

Aluminum circles are lightweight, durable, and corrosion-resistant, making them a popular choice for many industries.

Aluminum Circles Product Specification:

- Alloy: 1050, 1060, 1070, 1100, 3002, 3003, 3004, 5052A, 5052, 5754, 6061

- Hardness: O, H12, H14, H16, H18

- Thickness: 0.012″ – 0.15″ (0.3mm – 4mm)

- Diameter: 3.94″ – 38.5″ (80mm -2000mm)

- Surface: Polished, Bright, Anodized

- Usage: Suitable for making pots, pans, pizza trays, pie pans, cake pans, covers, kettles, basins, fryers, light reflectors

- Stamping Materials Include: steel, galvanized steel, aluminum, aluminum alloy and other metals

1. Thickness: The thickness of aluminum wafers generally ranges from 0.2mm to 10mm. The specific thickness selection depends on the usage requirements and process conditions.

2. Diameter: The diameter of the aluminum circle can be processed into different sizes according to needs, and the diameter range is usually between 5mm and 2000mm.

3. Material: Common materials of aluminum discs include 1050, 1060, 1100, 3003, 5052 and 6061 series. Different materials have different chemical compositions and physical properties and need to be selected according to the specific use environment.

4. Surface treatment: Aluminum wafers can be surface treated by anodizing, electrophoretic painting, spraying, frosting, etc. to improve the surface finish, corrosion resistance, surface hardness and other properties of the aluminum wafers.

5. Processing technology: Aluminum discs can be processed by shearing, punching, cutting, pressing, rolling and other processing techniques, and can be formed into products of various sizes and shapes.

Aluminum discs are a commonly used metal material with excellent properties such as lightness, toughness, and corrosion resistance.

They can also be surface treated and processed, and are widely used in construction, transportation, machinery, electronics and other fields.

The following is an introduction to the uses and specifications of aluminum discs.

1. Construction field: Aluminum discs can be used as building curtain wall materials. They can be made into various shapes, are light and beautiful, can withstand strong winds, heavy rain, sun and other weather conditions, and will not cause corrosion, deformation, etc. for long-term use.

At the same time, aluminum discs can also be used as interior decoration materials, made into various shapes, which are beautiful and elegant, can increase the visual effect of the space, and are also waterproof and fireproof.

2. Transportation field: Aluminum circle can be used as parts for vehicles such as cars, trains, ships, etc. Because aluminum discs have the advantages of light weight, high strength, corrosion resistance, etc., they can reduce the weight of the vehicle and improve the safety of the vehicle. , speed and durability.

At the same time, aluminum discs can also be used as partitions, decks, superstructures and other components of ships, with good water resistance and wind pressure resistance.

3. Mechanical field: Aluminum discs can be used as mechanical parts, guide rails, bearings, etc. Because aluminum discs have good wear resistance, corrosion resistance and electrical conductivity, they can meet various needs of the machinery manufacturing industry and also It can reduce the weight of mechanical parts and improve the performance of machinery.

4. Electronic field: Aluminum discs can be used as the main electrode material of electrolytic capacitors. They have the characteristics of high conductivity, low density, and good chemical stability, and can meet the needs of use at high frequencies and high temperatures.

At the same time, aluminum discs can also be used as electronic heat sink materials, which can effectively dissipate heat, reduce the temperature of electronic components, and improve the performance of electronic components.

5. Pressure vessel field: Aluminum discs can be used as the main material of pressure vessels. They can withstand high pressure and high temperature.

They also have excellent corrosion resistance and can meet the needs of various industries, such as petrochemicals, gas storage and transportation, and Medical equipment, etc.