2mm aluminum circle manufacturer china price | RuiYi Alumino

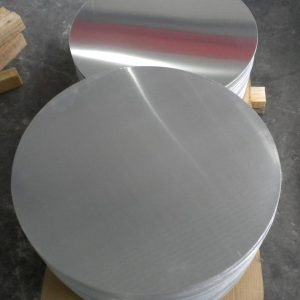

Aluminum circle is also called as aluminum circle sheet, which is a perfect material for making cookware like aluminum pan, aluminum pot, aluminum rice cooker, aluminum cooking utensils, aluminum pressure cooker and so on.

An aluminum circle, also known as an aluminum disc, is a versatile material used for creating round metal components.

These circular pieces typically have a thickness ranging from 0.3mm to 10mm and a diameter spanning 100mm to 800mm. They find applications in various industries, including electronics, daily chemicals, medicine, culture and education, and auto part

Aluminum circles are widely used in electronics, daily chemicals, medicine, culture, education and auto parts. Electrical appliances, insulation, machinery manufacturing, automobiles, aerospace, military industry, molds, construction, printing and other industries.

Kitchenware supplies such as non-stick pans, pressure cookers, etc. and hardware supplies such as lampshades, water heater shells, stretched tanks, etc. are among the most widely used deep-processed products of aluminum alloy plates and strips.

Our aluminum circles are made in accordance with international standards ASTM B209, ASME SB 221, EN573, and EN485

| Deep drawing aluminum circle/disc 1050, 1060, 1100, 1200, 3003, 3004, 3105, etc. | |||

| Aluminum Alloy | Thickness(mm) | Diameter(mm) | Temper |

| 1050, 1060, 1100 | 0.3-8.0 | 15-1200 | HO, H12, H14, H22, H24 |

| 3003, 3004, 3105 | 0.3-8.0 | 15-1200 | HO, H12, H14, H22, H24 |

| Material process | CC AND DC (DC For cookware and CC for road sign) | ||

| DC for cookware with good deep drawing and spinning | |||

| Further Fabrication | Deep Drawing, Spinning, Anodizing | ||

| Customize size | Size can be produced as per clients requirement | ||

| Surface | Mill finish, or color coated or anodized | ||

| MOQ per size | 3 tons | ||

| Quality Standard | ASTM B209, EN573-1 | ||

| Price terms | FOB, CRF, CIF | ||

| Payment Terms | 30% deposit in advance, 70% balance payment by TT or LC | ||

| Surface | Mill Finish, Plain | ||

| Standard | GB/T, ASTM, EN | ||

| Delivery time | Within 25 days after receipt of the lc or deposit | ||

| Material Quality | Totally free from defects like roll makers, edge damage, oil stain, white rust, dents, scratches, etc. A+++ quality | ||

| Equipment | 6 hot tandem rolling line, 5 cold mill production lines | ||

| Application | DC hot roll for cookware and utensils and CC for road signs | ||

| Packing | Standard export worthy wooden pallets, and standard packing is about 1 ton/pallet. Pallet weight also can be as per client’s requirement, and one 20′ can be loaded about 25mts. | ||

| Loading Port | Any port of China, Shanghai & Ningbo &Qingdao | ||

Aluminum circle mainly involve coil width, coil thickness, coil weight and blanking diameter.

The coil width (mm) range is 500-1250, 800-1400, 1000-1600

The coil thickness (mm) range is 0.4-3.0, 1.0-6.0

The coil weight (kg) is 8000, 10000

The range of blanking diameter (mm) is 85-660, 85-750, 100-900.

What are benefits of using aluminum circles?

Aluminum discs have the following characteristics:

Lightweight: Aluminum discs have a relatively low density and are lighter in weight than other metals such as steel. This makes aluminum discs an ideal choice in many applications to reduce the load on the structure.

High strength: Despite its light weight, aluminum discs still have high strength and can withstand a certain amount of pressure and load.

Corrosion resistance: Aluminum circles have good corrosion resistance and can resist the erosion of air, water, acid, alkali and other corrosive media, especially in atmospheric environments.

A very thin oxide film will be formed on its surface. This oxide film can effectively prevent the aluminum disc from corroding due to contact with oxygen, water and other substances in the external environment.

In addition, aluminum wafers can also be surface treated (such as anodizing, spraying, etc.) to increase their corrosion resistance to meet the needs of different fields.

Good thermal conductivity: Aluminum discs have good thermal conductivity and can quickly conduct heat to the surrounding environment, making them ideal for radiators and other applications that require materials with excellent thermal conductivity.

High electrical conductivity: Aluminum discs have good electrical conductivity and can conduct current and withstand electrical energy loads.

Aluminum discs are widely used in the manufacture of electronic products such as wires, cables, and battery cases.

Recyclable: Aluminum discs are a recyclable material that can be recycled to save resources and reduce environmental pollution.

Beautiful appearance: The aluminum disc has a smooth and bright surface and has good decorative properties. Therefore, aluminum discs are widely used in architectural decoration, automobile manufacturing, household products and other fields.

Environmentally friendly and sustainable: Aluminum discs will not pollute the environment and can be recycled and reused after being discarded, reducing resource waste and environmental damage. During the production and processing of aluminum wafers, relatively few harmful substances are emitted.

Relatively low price: Compared with other metal materials, the price of aluminum discs is relatively low, and the cost is relatively low. This gives aluminum wafers a competitive advantage in multiple fields and can better meet public demand.

The light weight, high strength, good thermal conductivity and good processability of aluminum discs make them the preferred material in many industries.

However, when choosing whether to use it and how to use it, you should also pay attention to the matching of its performance with the actual use requirements and environment.