China 3003 Aluminum clad sheet Manufacturer and Supplier

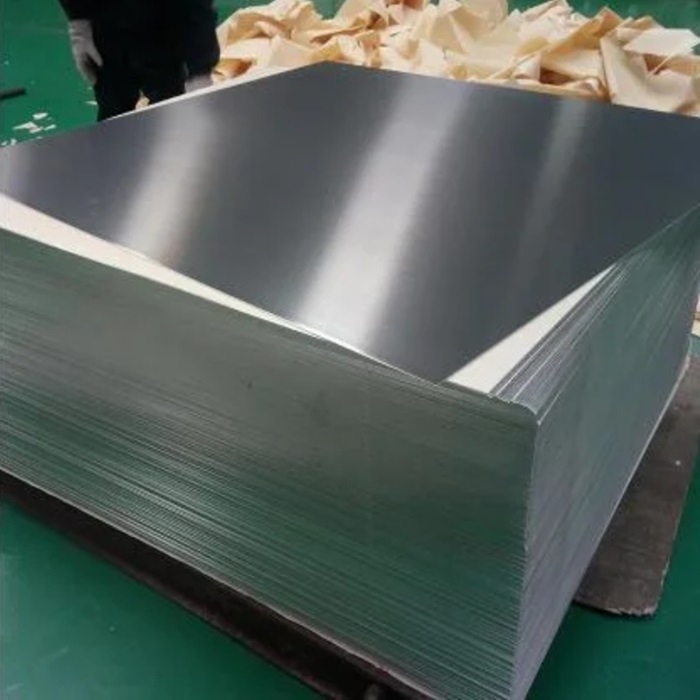

Aluminum clad sheet is a type of material that consists of a layer of aluminum bonded to a base metal, such as steel or copper.

This combination of materials provides the strength and durability of the base metal, while also benefiting from the corrosion resistance and lightweight properties of aluminum.

Aluminum clad sheet is commonly used in the manufacturing of automotive parts, household appliances, and building materials.

| Product Name | Aluminium Alloy laminated FoH for Brazing Heat Exchangers |

| Specification Ranges | <0.050.20) x (12-1300) |

| Alloy | 4343/3003/4343, 4343/3003+1.0%Zn/4343, 4343/3OO3+1.5%Zn/4343, 4343/3Z19/4343, 4045/3003/4045, |

| Temper | 0. H14. H24. H18 |

| Aplication Area | Used for outer-fln or Inner-fln of Inter Cooler, etc |

Clad aluminum is a material that has gained significant popularity in various industries due to its unique properties and applications. Combining the advantages of both aluminum and other metals, clad aluminum offers a versatile and cost-effective solution for a wide range of applications, from aerospace and automotive to consumer goods and construction.

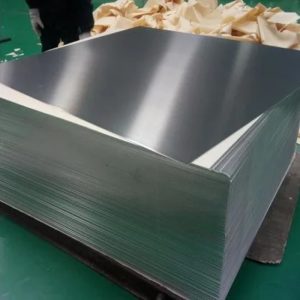

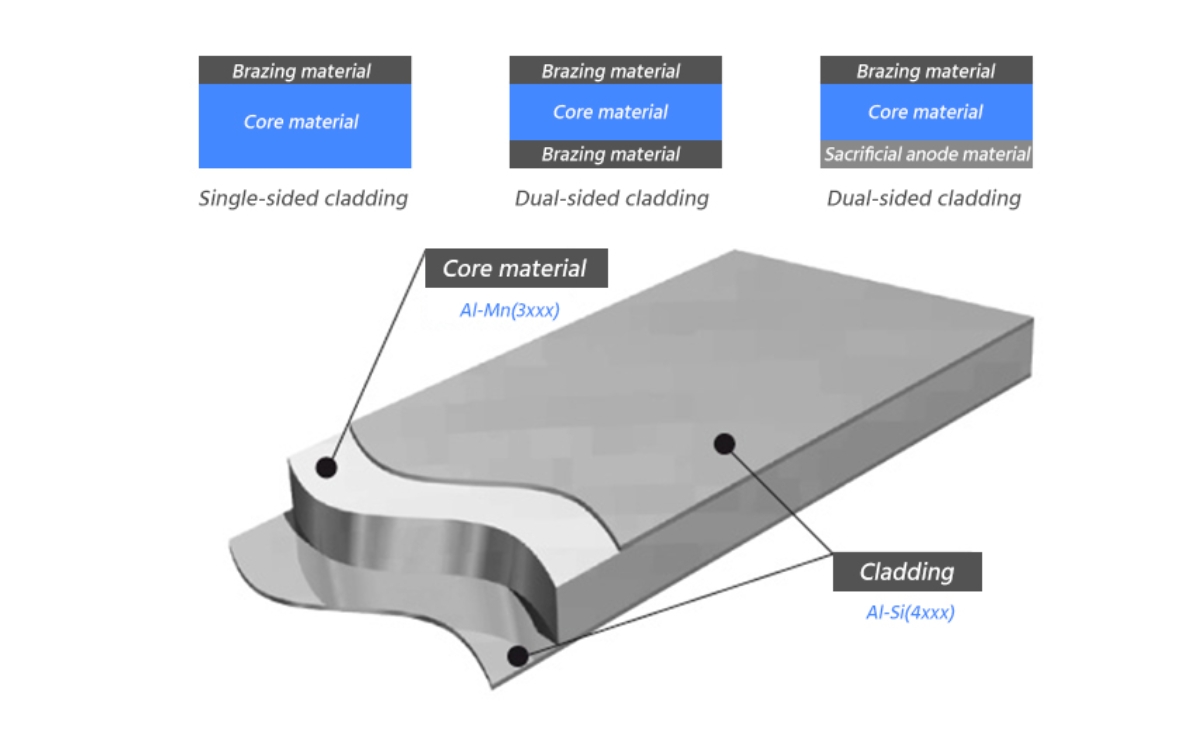

Clad aluminum is typically produced through a process called cladding, where a thin layer of one metal is bonded to a base material of aluminum. This can be achieved through various methods, such as roll bonding, explosive bonding, and diffusion bonding. The choice of cladding material can vary depending on the required properties of the final product. Common metals used for cladding include stainless steel, copper, and titanium.

One of the key advantages of clad aluminum is its enhanced performance compared to pure aluminum. By combining different metals, clad aluminum can exhibit improved strength, corrosion resistance, conductivity, and other desirable properties. This makes it an ideal material for applications that require specific performance characteristics while still benefiting from the lightweight nature of aluminum.

In the aerospace industry, clad aluminum is often used for aircraft structures, as it offers a high strength-to-weight ratio and excellent corrosion resistance. The automotive sector also utilizes clad aluminum for components that require both strength and lightness, such as body panels and structural components.

Clad aluminum can also be found in everyday consumer products, such as cookware, where the combination of aluminum and a stainless steel or copper cladding layer provides even heat distribution and durability. In architecture and construction, clad aluminum is used for façades, roofing, and other applications that require both aesthetic appeal and weather resistance.

Overall, clad aluminum is a versatile material that offers a unique combination of properties, making it suitable for a wide range of applications across various industries. Its ability to enhance the performance of aluminum while maintaining its lightweight characteristics has made it a popular choice for manufacturers looking to optimize product design and performance.

Aluminum Clad Sheet: A Versatile Solution for Diverse Applications

Aluminum clad sheet, also known as aluminum composite material (ACM) or aluminum sandwich panel, is a versatile building material that has gained popularity in various industries due to its unique properties and wide range of applications.

Comprising a lightweight yet sturdy core material sandwiched between two aluminum sheets, the aluminum clad sheet offers a host of benefits such as durability, design flexibility, weather resistance, and ease of fabrication.

This article explores the characteristics, advantages, and applications of aluminum clad sheet in different industries.

Characteristics of Aluminum Clad Sheet:

1. Lightweight and Durable: The combination of aluminum and the core material, usually made of polyethylene or fire retardant materials, results in a lightweight yet durable product that is ideal for a variety of applications.

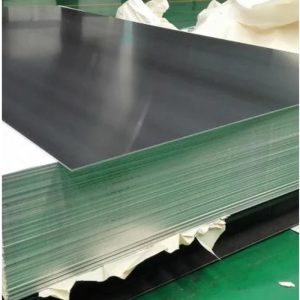

2. Weather Resistance: The aluminum cladding provides excellent protection against harsh weather conditions, UV rays, corrosion, and extreme temperatures, making it suitable for both interior and exterior applications.

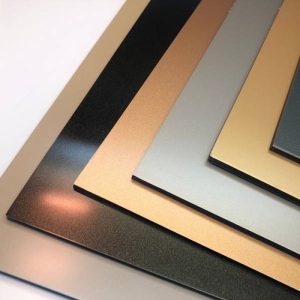

3. Design Flexibility: Aluminum clad sheet is available in a wide range of colors, finishes, textures, and sizes, allowing for versatile design options to meet the specific requirements of different projects.

4. Easy to Fabricate: Aluminum clad sheet can be easily cut, shaped, bent, drilled, and installed, providing ease of fabrication and customization for various applications.

Advantages of Aluminum Clad Sheet:

1. Thermal Insulation: The core material in aluminum clad sheet can provide thermal insulation properties, helping to regulate temperature and reduce energy costs in buildings.

2. Fire Resistance: Some aluminum clad sheets are designed with fire-retardant cores, offering increased fire resistance and safety in applications where fire protection is essential.

3. Low Maintenance: Aluminum clad sheets are easy to clean and require minimal maintenance, making them a cost-effective and long-lasting solution for architectural projects.

4. Eco-Friendly: Aluminum is a recyclable material, and many aluminum clad sheets are manufactured using sustainable practices, contributing to environmental sustainability and green building initiatives.

Applications of Aluminum Clad Sheet:

1. Architecture: Aluminum clad sheets are widely used in architectural projects for building facades, curtain walls, roofing, and decorative elements due to their aesthetic appeal, durability, and weather resistance.

2. Transportation: The lightweight and durable nature of aluminum clad sheets make them suitable for applications in the transportation industry, including vehicle bodies, trailers, and signage.

3. Signage and Displays: Aluminum clad sheets are popular for signage, billboards, displays, and exhibition stands due to their smooth surface, ease of printing, and ability to withstand outdoor conditions.

4. Industrial Applications: Aluminum clad sheets are utilized in industrial settings for cladding, enclosures, machinery panels, and modular structures that require strength, durability, and resistance to harsh environments.

In conclusion, aluminum clad sheet is a versatile and durable material that offers a wide range of benefits and applications across various industries.

Its lightweight nature, design flexibility, weather resistance, and ease of fabrication make it an ideal choice for architectural, transportation, signage, and industrial projects.

With its combination of functionality and aesthetic appeal, aluminum clad sheet continues to be a go-to solution for diverse applications that require high performance and long-term durability.