China Ck75 Steel C75s C75 SAE 1075 spring steel strip

CK75 steel is a high-carbon steel material, with C indicating a carbon content of 0.75%. Other main alloying elements include manganese, silicon, phosphorus, etc.

The CK75 Steel has the following properties and applications:

Characteristic of CK75 Steel:

It has high yield strength and tensile strength and can withstand large tensile loads.

It has good mechanical properties and heat treatment properties, and is suitable for manufacturing springs that require high strength and wear resistance.

Its hardness can be adjusted through heat treatment to meet the needs of different application scenarios.

It has a certain magnetic permeability and can be used to manufacture electromagnetic components.

It has good corrosion resistance and can maintain good surface finish and weather resistance under certain conditions.

Application of CK75 Steel:

Automotive industry: used to manufacture automobile chassis springs and suspension system parts.

Machinery manufacturing: used to manufacture various mechanical springs, mechanical parts and tools.

Electronic and electrical fields: used to manufacture electromagnetic components and conductive springs.

Construction and furniture: used to manufacture door and window hardware accessories and furniture springs, etc.

Suitable for making very large springs, such as stacked leaf springs on bulldozers, large coil springs and large torsion springs on ships.

CK75 Steel are equivalent to AISI 1075 carbon steel include:

ASTM A29 (1075)

ASTM A510 (1075)

ASTM A713 (1075)

SAE J403 (1075)

SAE J412 (1075)

EN10132 Standard SAE1075 cold rolled carbon steel strip CK75 C75 C75S Spring steel strip has a carbon content of 0.7-0.8% making it a multi-purpose carbon steel with good spring properties.

Therefore, it is a commonly used carbon steel in a wide range of engineering applications.

SAE1075 or CK75 contains 0.7-0.8% carbon, 0.15-0.35% silicon, 0.6-0.9% manganese, and 0.03% phosphorus and sulphur. It has a tensile strength of 1230-1340 MPa, yield strength of 1130-1240 MPa, and a hardness of 57-63 HRC.

CK75 spring steel has better hardenability, the critical hardenable diameter in oil can reach 100~150mm.

CK75 or C75 is Suitable for making very large springs, such as stacked leaf springs on bulldozers, large coil springs and large torsion springs on ships.

CK75 spring steel is a high-carbon steel material. Its chemical composition mainly includes carbon (C) content between 0.70-0.80%, silicon (Si) content between 0.10-0.35%, and manganese (Mn) content between 0.60-0.80%.

Between 0.90%, the contents of phosphorus (P) and sulfur (S) are less than 0.025% respectively.

CK75 spring steel has good elasticity and toughness and is often used to manufacture springs, blades, saw blades, knives and other parts and tools that require high strength and wear resistance.

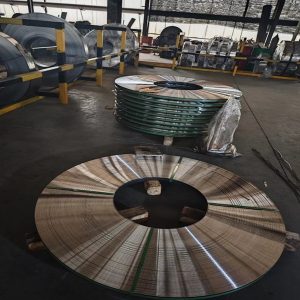

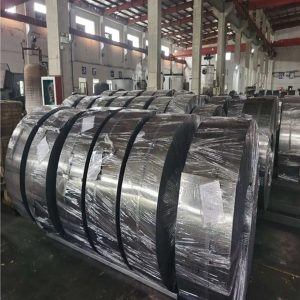

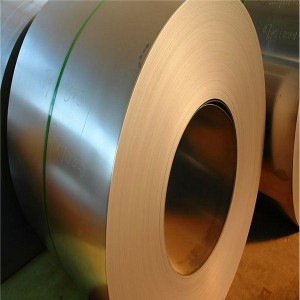

C75 C75s CK75 SAE 1075 spring steel strip

1,Delivery Conditions:

| Delivery Condition | Sizes | Surface | Edge |

| 1.Cold Rolled | 1.Thickness: 0.09-8mm | Bright / Polished / Blue/Yellow | Slit |

| 2.Cold Rolled+Hydrogen Annealed | 2.Width: 6-450mm | Round | |

| 3.Cold Rolled+Hardened+Tempered | Coil insider diameter: 300-800mm | Square |

2, Grades comparision:

| GRADES COMPARISON FOR SPRING STEEL | ||||||||

| CHINA GB/T | USA ASTM | JAPAN JIS | GERMANY DIN | FRANCE NF | BIRTAIN BS | ISO | KOREA KS | TAIWAN CNS |

| 45 | 1045 | S45C | CK45 | XC45 | C45 | |||

| 50 | 1050 | S50C | CK50 | XC50 | 080M50 | C50 | ||

| 60 | 1060 | S60C | CK60 | XC60 | 060A62 | C60 | ||

| 70 | 1070 | S70C | CK70 | XS70 | S70 | |||

| 75 | 1075 | S75C | CK75 | XC75 | C75 | |||

| T10 | W1-9 | SK4 | ||||||

| T9 | W1-8 | SK5 | ||||||

| SK85 | — | SK85 | ||||||

| 40Mn | 1043 | SWRH42B | 40Mn4 | 40M5 | 080A40 | SL,SM | ||

| 42Mn | ||||||||

| 65Mn | 1566 | S60C-CSP | CK67 | 080A67 | C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 /SUP7 | 55Si7 | 55Si7 | 251H60 | 55SiCr7 | ||

| 60Si2Mn | 9260 | SUP 6 / SUP7 | 65Si7 | 65Si7 | 251H60 | 61SiCr7 | SUP3 | SUP6 |

| 62Si2Mn | ||||||||

| 75Cr1 | 75Cr1 | 75Cr1 | 75Cr1 | |||||

| 51CrV4 | 5160 | SUP9A | 51CrV4 | 51CrV4 | SPS5A | SUP9A | ||

| 30CrMo | G41300 | SUP13 | 35CrMo4 | SPS9 | SUP13 | |||

| 50CrVA | 6150 | SUP10 | 51CrV4 | 51CrV4 | 735A51 | 51CrV4 | SPS6 | SUP10 |

3,Chemical Composition:

| Standard | Grade | Chemical Composition(%) | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | V | ||

| GB/T699 | 45 | 0.42~0.50 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 50 | 0.47~0.55 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 55 | 0.52~0.60 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 60 | 0.57~0.65 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 65 | 0.62~0.70 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 70 | 0.67~0.75 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 75 | 0.72~0.80 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn40 | 0.37~0.44 | 0.17~0.37 | 0.70~1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn45 | 0.42~0.50 | 0.17~0.37 | 0.70~1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn65 | 0.62~0.70 | 0.17~0.37 | 0.90~1.20 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T1298 | SK85/SK5 | 0.80 ~0.90 | ≤0.35 | ≤0.50 | 0.03 | 0.03 | 0.2 | 0.25 | 0.3 | |

| GB/T1298 | SK4 | 0.95~1.04 | ≤0.35 | ≤0.40 | 0.035 | 0.03 | 0.25 | 0.2 | 0.3 | |

| GB/T3077 | 51CrV4 | 0.47~0.55 | 0.17~0.37 | 0.80~1.10 | 0.035 | 0.035 | 0.90~1.20 | 0.3 | 0.3 | 0.10~0.20 |

| GB/T3077 | 50CrVA | 0.47~0.54 | 0.17~0.37 | 0.50~0.80 | 0.025 | 0.025 | 0.80~1.10 | 0.3 | 0.3 | 0.10~0.20 |

| GB/T3077 | 75Cr1 | 0.7~0.8 | 0.25~0.5 | 0.50~0.70 | 0.035 | 0.035 | 0.30~0.40 | |||

| GB/T1222 | 55Si2Mn | 0.52~0.60 | 1.50~2.00 | 0.60~0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

| GB/T1222 | 60si2Mn | 0.56~0.64 | 1.50~2.00 | 0.60~0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |