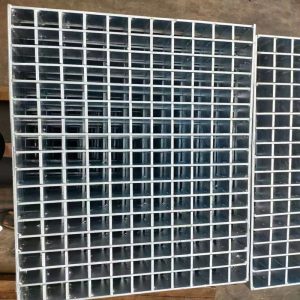

China Galvanized Steel Grating Manufacturer and Supplier

Galvanized steel grating is a versatile and durable material that is commonly used in industrial and commercial applications.

It is made from steel that has been coated with a protective layer of zinc, which helps to prevent corrosion and extend the lifespan of the material.

This type of grating is popular for its strength, corrosion resistance, and low maintenance requirements. One of the main benefits of galvanized steel grating is its strength.

It is able to withstand heavy loads and high traffic levels, making it ideal for use in areas where there is a lot of foot or vehicle traffic.

This makes it a popular choice for industrial settings, such as manufacturing plants, warehouses, and factories.

In addition to its strength, galvanized steel grating is also known for its corrosion resistance. The zinc coating helps to protect the steel from rust and corrosion, even in harsh environments such as outdoor settings or areas with high levels of moisture.

This means that galvanized steel grating is able to maintain its integrity and appearance over time, making it a cost-effective option for many applications.

Another advantage of galvanized steel grating is its low maintenance requirements. Unlike other materials that may require regular painting or coating to prevent corrosion, galvanized steel grating is able to maintain its protective layer of zinc for an extended period of time with minimal upkeep.

This helps to reduce the overall cost of ownership and makes it a popular choice for many businesses and industries.

Overall, galvanized steel grating is a durable, versatile, and cost-effective material that is well-suited for a wide range of industrial and commercial applications.

Its strength, corrosion resistance, and low maintenance requirements make it an ideal choice for areas that require a high level of durability and reliability.

Whether used in walkways, platforms, or drainage systems, galvanized steel grating is sure to provide years of reliable service.

Galvanized steel grates, also know as welded steel bar grating, the most strong and durable metal grating products.

They are made from the mild carbon steel or stainless steel materials. We provide a full solution of 19-w-4 bar grating, press locked grating,heavy duty grating, steel stair treads,plank gratings,safety grating, trench cover,etc.

All the gratings are extremely strong and durable for all the bearing application. And all grating products are fully recyclable.

Due to the extremely strong and durable for all the bearing application,galvanized steel grates has become the most popular grating in the markets.The stability makes them have a much higher performance in the application.

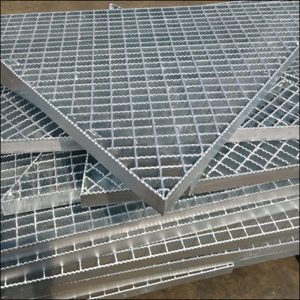

We also can shear or form the steel gratings to any specification or desired shape. Because of those excellent characteristic,the galvanized steel grates can be widely used in flooring,deck,walkway,platform, decoration,etc.

- Materials:

Mild Carbon Steel

Stainless Steel 304,316 - Surface treatment:

Hot dipped Galvanized

Painting

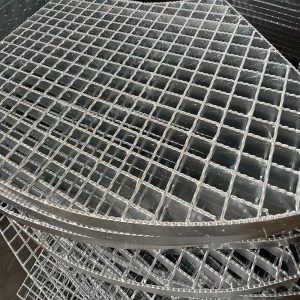

- Cross bars : Dia. 5mm,6mm,8mm (Round bar)/5*5mm,6*6mm,8*8mm (Twist bar)

- Cross bar spacing : 40,50,60,65,76,100,101.6,120,130mm, etc.

- Bearing bars : 20*5,25*3,25*4,25*5,30*3,30*4,30*5,32*3,32*5,40*5,50*4… 75*8mm, etc.

- Bearing bar spacing : 20,25,30,32.5,34.3,40,50,60,62,65mm

Galvanized steel grates are available in a variety of bearing bar thicknesses,depth and spacing according to the applications and loading requirements.

They are also available in either smooth top or serrated of anti slip grating. As one of leading manufacturer and fabricator of electro forge welded steel grating in China, we supply a variety of sizes for shipment in panels or other specs.

Galvanized steel grates are widely used in flooring, catwalk, mezzanine,decking, stair tread, fencing, ramp, dock, trench cover, drainage pit cover, maintenance platform, wash rack, ventilation screen, storage rack, window and machinery safe guards, workshop, motor rooms, trolley channel, heavy loading area, boiler equipment and heavy equipment area.

The stainless steel grating is used in and is also used in many gas and oil producers,chemical plants,food processing facilities and other commercial,architectural applications.

Galvanized Steel Grating Vs Aluminum Grating

When it comes to choosing the right grating material for your project, it’s essential to consider factors such as durability, strength, and cost.

Galvanized steel grating and aluminum grating are two popular choices, each with its advantages and disadvantages.

In this article, we will compare the two materials to help you make an informed decision.

Galvanized steel grating is made from carbon steel that has been coated with a layer of zinc to prevent corrosion.

This makes it extremely durable and resistant to rust, making it an excellent choice for outdoor applications.

Galvanized steel grating is also known for its high strength, making it suitable for heavy-duty projects such as industrial flooring and walkways.

On the other hand, aluminum grating is lightweight and easy to install, making it a popular choice for applications where weight is a concern.

Aluminum grating is also highly resistant to corrosion, making it ideal for outdoor use. However, aluminum grating is not as strong as galvanized steel grating, so it may not be suitable for heavy-duty applications.

In terms of cost, galvanized steel grating is typically more affordable than aluminum grating. However, aluminum grating may be a more cost-effective option in the long run due to its low maintenance requirements and long lifespan.

Overall, the choice between galvanized steel grating and aluminum grating will depend on the specific requirements of your project.

If you need a strong and durable material for heavy-duty applications, galvanized steel grating may be the best choice.

On the other hand, if weight is a concern and corrosion resistance is paramount, aluminum grating may be the better option.

In conclusion, both galvanized steel grating and aluminum grating have their advantages and disadvantages.

By carefully considering your project’s requirements and budget, you can choose the material that best suits your needs.