China 8MM Steel Bar Grating Manufacturer and Supplier | Ruiyi

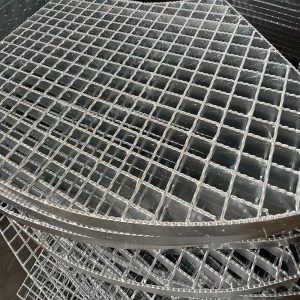

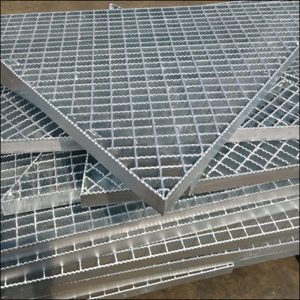

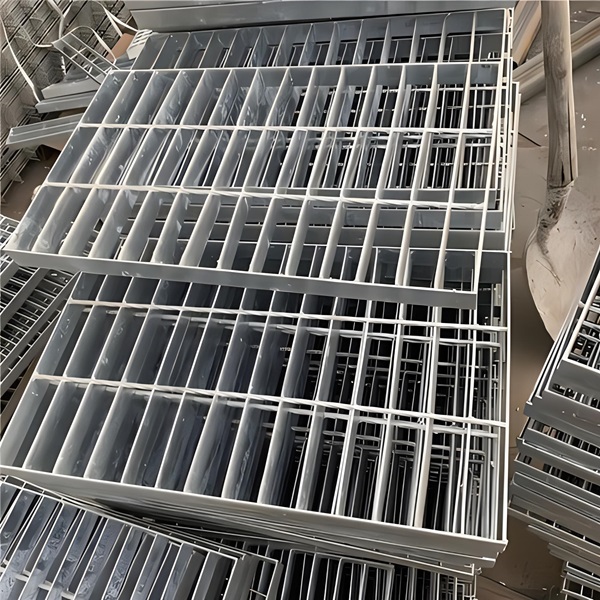

Steel bar grating is typically made from carbon steel or stainless steel, which provides high strength and corrosion resistance. The grating is available in various patterns, such as bar grating, expanded metal grating, and perforated metal grating, to suit different applications and load requirements.

Steel bar grating is a type of grating made from steel bars or sheets that are joined together to form a grid-like structure. It is commonly used in industrial settings, such as factories, warehouses, and outdoor areas, due to its strength, durability, and ability to withstand heavy loads.

Some common uses of steel bar grating include:

1. Walkways and platforms: Steel grating is often used to create safe and secure walkways and platforms in industrial settings. It provides a non-slip surface and allows for drainage of liquids and debris.

2. Stair treads: Steel grating can be used as stair treads to provide safe and sturdy steps in industrial and commercial buildings.

3. Drainage covers: Steel grating is commonly used as covers for drains and manholes. It allows for the flow of water and prevents debris from entering the drainage system.

4. Fencing and barriers: Steel grating can be used as fencing or barriers in outdoor areas to provide security and prevent unauthorized access.

5. Shelving and storage racks: Steel grating can be used as shelves or storage racks in warehouses and factories. It provides a strong and durable surface for storing heavy items.

Overall, steel grating is a versatile and reliable material that is widely used in various industries for its strength, durability, and functionality.

Steel bar grating is one of our main grating products,also know as press weld steel bar grating.Due to the extremely strong and durable for all the bearing application,which become the most popular grating in the markets.The stability makes them have a much higher performance in the application.

- Materials: Mild steel,Stainless steel, Aluminum

- Surface treatment: Galvanized or Original

Specification:

- Cross bars : Dia. 5mm,6mm,8mm (Round bar)/5*5mm,6*6mm,8*8mm (Twist bar)

- Cross bar spacing : 40,50,60,65,76,100,101.6,120,130mm, etc.

- Bearing bars : 20*5,25*3,25*4,25*5,30*3,30*4,30*5,32*3,32*5,40*5,50*4… 75*8mm, etc.

- Bearing bar spacing : 20,25,30,32.5,34.3,40,50,60,62,65mm

Steel bar grating is available in a variety of bearing bar spacing,thicknesses and depth according to the applications and loading requirements. They are also available in either smooth top or serrated for anti-slip.

Galvanized steel bar grating is made from hot-dip galvanized steel, which provides excellent corrosion resistance and ensures long-lasting durability. It can withstand harsh outdoor conditions, including exposure to rain, snow, sunlight, and chemicals

Steel Bar Grating

Galvanized steel bar grating is known for its high strength-to-weight ratio. It can support heavy loads without bending or breaking, making it ideal for outdoor applications where strength is crucial, such as walkways, platforms, and industrial flooring.

Aluminum grating and steel grating are both popular choices for various industrial and commercial applications. However, there are some key differences between the two materials:

1. Material Composition: Aluminum grating is made from lightweight aluminum alloy, while steel grating is made from carbon steel or stainless steel.

2. Weight: Aluminum grating is significantly lighter than steel grating, making it easier to handle and install. This can be advantageous in applications where weight is a concern, such as pedestrian walkways or platforms.

3. Corrosion Resistance: Aluminum grating has excellent corrosion resistance, especially in outdoor or corrosive environments. It forms a natural oxide layer that protects it from rust and other forms of corrosion. On the other hand, steel grating is susceptible to rust and requires additional coatings or treatments to enhance its corrosion resistance.

4. Strength and Load Capacity: Steel grating is generally stronger and has a higher load capacity compared to aluminum grating. It can withstand heavy loads and is often used in applications where high strength and durability are required, such as industrial flooring or bridge decks.

5. Cost: Aluminum grating is typically more expensive than steel grating due to the higher cost of aluminum as a raw material. However, the cost difference may be justified by the benefits of its lightweight, corrosion resistance, and low maintenance properties.

6. Aesthetics: Aluminum grating has a more modern and sleek appearance compared to steel grating. It is often used in architectural applications where aesthetics are important, such as building facades or decorative walkways.

Ultimately, the choice between aluminum grating and steel grating depends on the specific requirements of the application. Factors such as load capacity, corrosion resistance, weight, and cost should be considered to determine the most suitable option.