China Galvanized Steel Grating Bar Manufacturer and Supplier

Galvanized steel grating has strong impact resistance, strong corrosion resistance and heavy load-bearing capacity, beautiful and elegant, and has superior performance in municipal roadbed and steel platform construction projects. The extremely high cost performance is the reason why galvanized steel grating is widely used in the paving projects of new and old roadbed gutter roads.

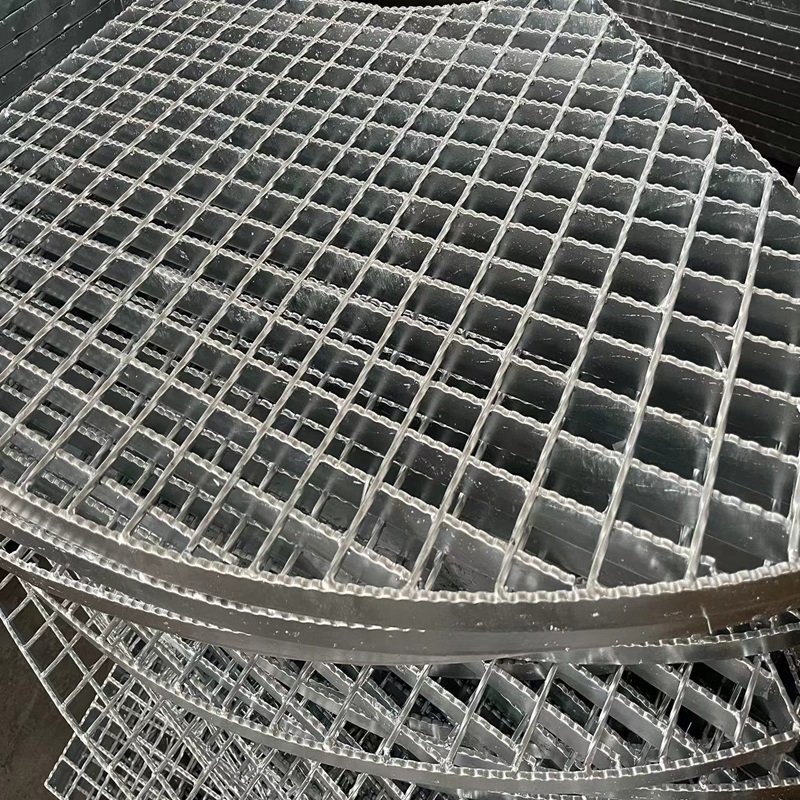

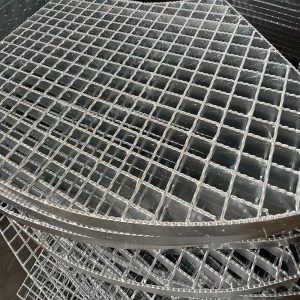

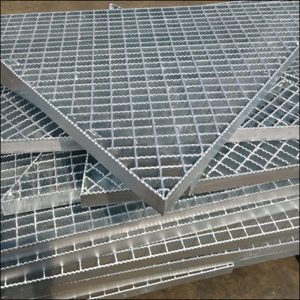

Galvanized grating, also known as galvanized bar grating, is a grid-like metal sheet made of mild steel flat bars and twisted square bars welded horizontally and vertically. The surface of galvanized steel grating is treated with special hot-dipped galvanization, which has stable chemical and physical properties and is not easily corroded by air oxidation and microorganisms.

Top Metal is the best place to go for all your Galvanized steel gratings needs. Our factory have over 15 years of experience and our team will be happy help you with any welding, shearing or cutting project that comes up!

There are 3 types of steel grating: hot-dip galvanized steel grating and Press-locked Galvanized steel grating and Welded Galvanized steel grating.

Hot-dip galvanized steel grating is also known as hot-dip galvanizing, involves melting zinc ingots at high temperatures, putting in some auxiliary materials, and then dipping the structural metal parts into a galvanizing bath to attach a zinc layer to the metal parts.

The advantage of hot-dip galvanizing is its strong anti-corrosion ability, good adhesion and hardness of the galvanized layer. The weight of the product increases after galvanizing, and the amount of zinc we often refer to is mainly for hot-dip galvanizing.

Press-locked Galvanized steel grating is made of low carbon steel and stainless steel. It is a grid formed by welding or press-locking cross bars to bearing bars. The press-locked grating has the characteristics of high strength, light structure, high bearing capacity, anti-corrosion and so on.

The press-locked grating is widely used in power plants, chemical plants, oil refineries, steel mills, machinery factories, shipyards, paper mills and other industries.

Welded Galvanized steel grating is made of low carbon steel or stainless steel. It is widely used in construction, petroleum, chemical industry, power plant, sewage treatment plant, food processing plants and other industries.

The surface of the Welded Galvanized steel grating is hot dip galvanized or electro-galvanized. The hot dip galvanized layer is thick and the electro-galvanized layer is thin. It has good corrosion resistance and anti-rust properties.

Welded Galvanized steel grating is divided into two kinds of bearing bars: flat bar and I-bar. The distance between the two bearing bars is called pitch or pitch

Galvanized grating is a great choice for any number of applications. It is durable, versatile, and strong, making it an ideal solution for a variety of needs.

Galvanized grating is a type of grating made from steel that has been coated with a layer of zinc through a process called galvanization. This process helps to prevent corrosion and increase the lifespan of the grating, making it more durable and suitable for outdoor applications.

Galvanized steel grating is commonly used in industrial and commercial settings where there is a need for strong and reliable flooring or platform solutions. It is often used for walkways, stair treads, ramps, drainage covers, and other applications that require a sturdy and slip-resistant surface.

The grating is typically made from flat bars or round bars that are welded together to form a grid-like pattern. The galvanized coating helps to protect the steel from rust and corrosion caused by exposure to moisture, chemicals, and other environmental factors.

Galvanized steel bar grating is known for its high strength, load-bearing capacity, and resistance to impact and deformation. It is also easy to install, maintain, and clean. Additionally, the open design of the grating allows for the passage of light, air, and liquids, making it suitable for applications where drainage or ventilation is required.

| Specification | Description |

|---|---|

| Material | ASTM A36, GB Q235, S235JR, ASTM A572-50, GB Q345B, S355JR |

| Manufacturing Process | Welded, swage-locked, or press-locked |

| Surface Treatment | Hot-dip galvanized |

| Surface Type | Standard plain surface, serrated surface |

| Cross Bar Spacing | Customizable, typically 2″ or 4″, center to center |

| Bearing Bar Spacing | Customizable, typically 15/16″ or 1-3/16″, center to center |

| Bearing Bar Height | Customizable, typically 20mm to 60mm |

| Bearing Bar Thickness | Customizable, typically 2mm to 5mm |

| Cross Bar Size | Customizable, typically 4mm to 10mm diameter |

| Slip Resistance | Serrated or plain surface, depending on the application |

| Installation Method | Welding, clips, or bolts and nuts, depending on the application |

| Compliance | Meets industry standards and applicable building codes, including ASTM, ISO, and ANSI/NAAMM |

Overall, galvanized steel grating is a popular choice for various industrial and commercial applications due to its durability, corrosion resistance, and cost-effectiveness.