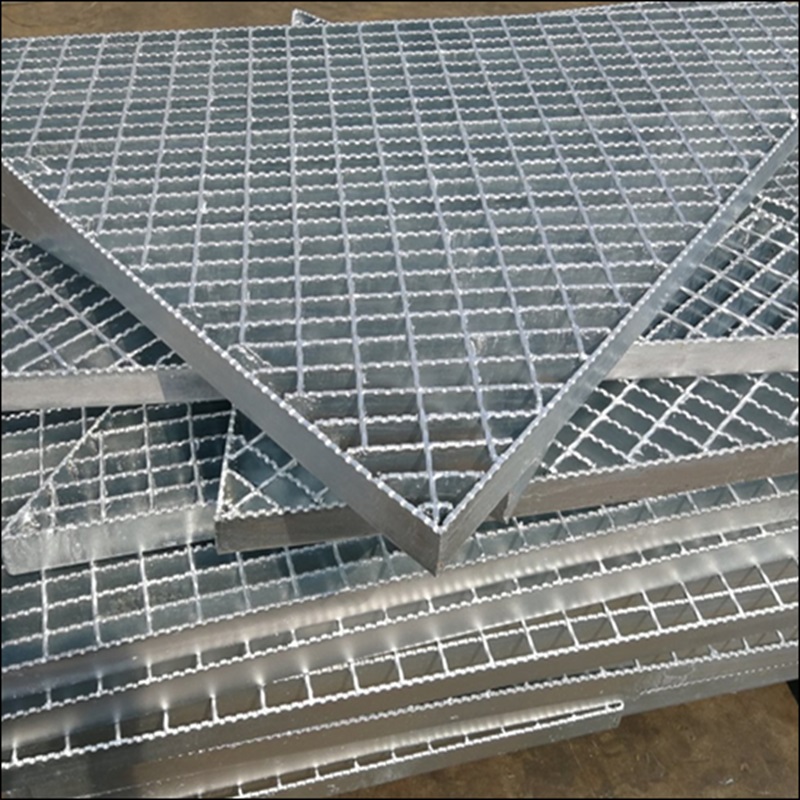

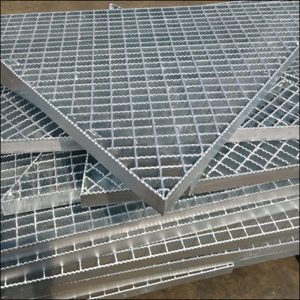

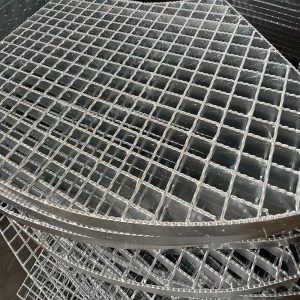

China Hot Dipped Galvanized Metal Steel Grating Manufacturer

Steel grating is typically made from carbon steel or stainless steel, which provides high strength and corrosion resistance. The grating is available in various patterns, such as bar grating, expanded metal grating, and perforated metal grating, to suit different applications and load requirements.

Hot-dip galvanized grid, also known as hot-dip galvanized steel grating, is a grid-shaped building material made of low carbon steel flat steel and twisted square steel welded horizontally and vertically.

The production process of Galvanized Steel Grating

Raw material cutting:

The hot-dip galvanized steel plate is cut according to the requirements of the construction drawings. The cutting method can be CNC plasma cutting or laser cutting. After cutting is completed, the steel grating needs to be trimmed.

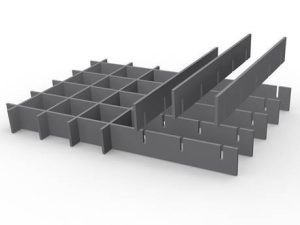

Steel grating pressure welding:

The trimmed steel grating plates are assembled into a grid-shaped steel grating product using a pressure welding process.

Using 200 tons of hydraulic resistance welding automation equipment, the load-bearing flat steel and cross bars are arranged and welded at a certain distance into the original plate, and then processed through cutting, drilling, hemming and other processes to form the product required by the customer.

Among them, the distance between load-bearing flat steel is usually 30MM and 40MM, and the distance between crossbars is usually 50MM and 100MM, but it can also be produced according to customer requirements.

Surface treatment: The steel grating products after pressure welding are pickled to remove impurities, oil stains, etc. on the surface to prepare for the later hot-dip galvanizing process.

Hot-dip galvanizing:

The pickled steel grating products are hot-dip galvanized in a high-temperature environment. The main purpose is to produce a galvanized layer on the surface of the steel grating product. This galvanized layer can prevent the steel grating from The product is corroded during use.

Steel grating is a type of grating made from steel bars or sheets that are joined together to form a grid-like structure. It is commonly used in industrial settings, such as factories, warehouses, and outdoor areas, due to its strength, durability, and ability to withstand heavy loads.

Some common uses of steel grating include:

1. Walkways and platforms: Steel grating is often used to create safe and secure walkways and platforms in industrial settings. It provides a non-slip surface and allows for drainage of liquids and debris.

2. Stair treads: Steel grating can be used as stair treads to provide safe and sturdy steps in industrial and commercial buildings.

3. Drainage covers: Steel grating is commonly used as covers for drains and manholes. It allows for the flow of water and prevents debris from entering the drainage system.

4. Fencing and barriers: Steel grating can be used as fencing or barriers in outdoor areas to provide security and prevent unauthorized access.

5. Shelving and storage racks: Steel grating can be used as shelves or storage racks in warehouses and factories. It provides a strong and durable surface for storing heavy items.

Overall, steel grating is a versatile and reliable material that is widely used in various industries for its strength, durability, and functionality.

7 Reasons Why Galvanized Steel Grating is Ideal for Outdoor Use

1. Durability: Galvanized steel grating is made from hot-dip galvanized steel, which provides excellent corrosion resistance and ensures long-lasting durability. It can withstand harsh outdoor conditions, including exposure to rain, snow, sunlight, and chemicals.

2. Strength: Galvanized steel grating is known for its high strength-to-weight ratio. It can support heavy loads without bending or breaking, making it ideal for outdoor applications where strength is crucial, such as walkways, platforms, and industrial flooring.

3. Slip Resistance: The surface of galvanized steel grating is typically serrated or anti-slip, providing excellent traction even in wet or slippery conditions. This makes it a safe choice for outdoor areas prone to moisture, such as ramps, stair treads, and drainage covers.

4. Easy Maintenance: Galvanized steel grating requires minimal maintenance. Its smooth surface allows for easy cleaning, and the galvanized coating provides protection against rust and corrosion, reducing the need for frequent repairs or replacements.

5. Cost-effective: Galvanized steel grating is a cost-effective solution for outdoor applications. Its long lifespan and low maintenance requirements translate into reduced overall costs over time. Additionally, its strength allows for the use of thinner materials, further reducing costs without compromising performance.

6. Versatility: Galvanized steel grating can be customized to meet specific design requirements. It is available in various sizes, shapes, and configurations, allowing for flexibility in outdoor projects. It can be easily cut or welded to fit different dimensions, making it suitable for a wide range of applications.

7. Environmental Friendliness: Galvanized steel grating is a sustainable choice for outdoor use. The galvanizing process involves coating the steel with a layer of zinc, which is a recyclable material. Additionally, the durability of galvanized steel grating reduces the need for frequent replacements, minimizing waste and environmental impact.

| Specification | Description |

|---|---|

| Material | ASTM A36, GB Q235, S235JR, ASTM A572-50, GB Q345B, S355JR |

| Manufacturing Process | Welded, swage-locked, or press-locked |

| Surface Treatment | Hot-dip galvanized |

| Surface Type | Standard plain surface, serrated surface |

| Cross Bar Spacing | Customizable, typically 2″ or 4″, center to center |

| Bearing Bar Spacing | Customizable, typically 15/16″ or 1-3/16″, center to center |

| Bearing Bar Height | Customizable, typically 20mm to 60mm |

| Bearing Bar Thickness | Customizable, typically 2mm to 5mm |

| Cross Bar Size | Customizable, typically 4mm to 10mm diameter |

| Slip Resistance | Serrated or plain surface, depending on the application |

| Installation Method | Welding, clips, or bolts and nuts, depending on the application |

| Compliance | Meets industry standards and applicable building codes, including ASTM, ISO, and ANSI/NAAMM |