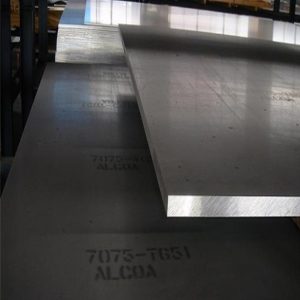

China 7475 T7351 aircraft aluminum Plate Manufacturer

7475 T7351 Aircraft aluminum Plate is a high-strength, high-hardness aviation-specific aluminum material. It is mainly used to manufacture key parts such as aircraft frames, skins, and landing gears.

7475 T7351 Aircraft aluminum Plate has good corrosion resistance, high fatigue resistance and good plastic toughness, and can maintain good performance under extreme temperature and pressure conditions.

7475-T7351 Aircraft aluminum plate is an American deformed aluminum alloy plate suitable for plate and plate applications requiring high strength, excellent fracture toughness and resistance to fatigue crack propagation.

Typical fracture toughness values for Alloy 7475 plate are approximately 40% higher than Alloy 7075 in the same condition. The durability and fatigue properties of Alloy 7475 are equal to and in some cases better than many current high-strength aerospace alloys such as 7075, 7050 and 2024.

Typical Application of Aviation aluminum Plate:

| Item | Grade | Temper | Application |

| 1 | 2024 | O,T351,T851 | Fuselage structure, wing tensile component, shear web, stiff structure section |

| 2 | 2014 | T851,T351 | Fuselage machining component, bulkhead, wing skins and other structure component for high performance military aircraft |

| 3 | 2324 | T39 | Lower wing skins and wing box component for commercial aircraft |

| 4 | 7050 | T7651,T7451 | fuselage ring, frame |

| 5 | 7150 | T6151,T7751 | Upper wing skins for large commercial airplane which requires resistant to high pressure, upper wing reinforce plate and lower horizontal stabilizer panel for civil and military aircraft |

| 6 | 7055 | T7751 | Upper wing structure, horizontal stabilizer, keel beam, seat track, freight slide track |

| 7 | 7075 | T651, T7651,O,T7351 | Airplane structure component required high strength, moderate toughness and moderate corrosion resistance |

| 8 | 7475 | T651,T7351 | Fuselage skin, wing skin, wing spar, fuselage bulkhead |

There are many specifications for aircraft aluminum plates, as follows:

Aluminum sheet specifications

Thickness: 0.1mm~10mm

Size: 1000mm×2000mm; 1220mm×1440mm~1500mm×4500mm.

Aluminum plate specifications

Thickness: 10mm to 450mm, with the small plate size being 1000mm×2000mm and the large plate size being 1220mm×2400mm~1500mm~3000mm.

The Role of 7475 T7351 Aircraft Aluminum Plate in Ensuring Flight Safety?

The role of 7475 T7351 aviation aluminum plate in ensuring flight safety is crucial. This specific type of aluminum plate is widely used in the aerospace industry for various aircraft components and structures due to its high strength, toughness, and corrosion resistance properties.

One of the primary applications of 7475 T7351 aviation aluminum plate is in the construction of aircraft wings and fuselages. These components are subjected to significant stress and loads during flight, and therefore, they need to be made from materials that can withstand these forces.

The high strength and toughness of 7475 T7351 aluminum plate make it an ideal choice for these critical parts of an aircraft.

Additionally, 7475 T7351 aviation aluminum plate is used in the manufacturing of landing gear components.

Landing gear systems are responsible for supporting the weight of an aircraft during takeoff, landing, and ground operations. These components need to be strong and durable to ensure safe landings and prevent any structural failures.

The high strength and corrosion resistance of 7475 T7351 aluminum plate make it suitable for these demanding applications.

7475 T7351 aviation aluminum plate offers a combination of high strength, excellent fatigue resistance, good corrosion resistance, weldability, heat treatability, lightweight, and machinability, making it an ideal material for various aircraft applications.

7475 T7351 aircraft aluminum plate has a high tensile strength of about 540 MPa (78,000 psi), making it one of the strongest aluminum alloys available. This high strength allows for the construction of lightweight yet strong aircraft structures.

Top Metal Manufacture / RAYIWELL MFG is a supplier of steel materials like aluminum sheet, Aluminum strip, aluminum coils, aluminum plate, aluminum checkered plate and carbon steel plate.

Top Metal Manufacture also sell cold rolled steel coils, SPCC, Galvanized steel sheet, SGCC, Galvalume steel coils, Aluzinc steel coils, prepainted Galvanized steel coil, PPGI and we can sell Non Grain oriented steel or CRNGO. We have products copper plate, alloy steel bar or Tungsten carbide materials available too.