China Wear Resistant Steel Plate BHNM400 BHNM450 BHNM500 Manufacturer and Supplier | Ruiyi

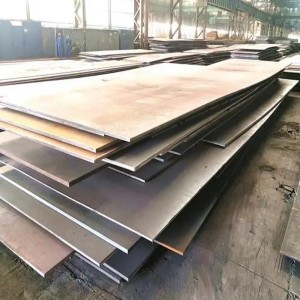

Wear Resistant Steel Plate refers to a special plate product specially designed for use under large-area wear conditions. Commonly used wear-resistant steel plates are plate products made by compounding a certain thickness of alloy wear-resistant layer with higher hardness and excellent wear resistance on the surface of ordinary low carbon steel or low alloy steel with good toughness and plasticity through surfacing method. In addition, there are cast wear-resistant steel plates and alloy quenched wear-resistant steel plates.

Wear-resistant steel plate consists of two parts: low carbon steel plate and alloy wear-resistant layer. The alloy wear-resistant layer is generally 1/3~1/2 of the total thickness. During operation, the matrix provides comprehensive properties such as strength, toughness and plasticity to resist external forces, and the alloy wear-resistant layer provides wear-resistant properties that meet the requirements of specified working conditions.

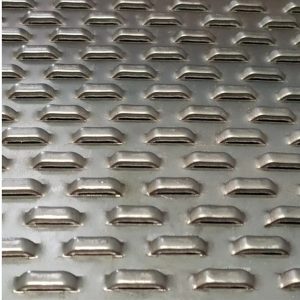

There is a metallurgical bond between the wear-resistant steel plate alloy wear-resistant layer and the base plate. Through special equipment and an automatic welding process, the high-hardness self-protecting alloy wire is evenly welded to the substrate. The number of composite layers is one to two or even multiple layers. During the composite process, due to the different shrinkage ratios of the alloys, uniform transverse cracks appear. This It is the distinguishing feature of wear-resistant steel plate

The alloy wear-resistant layer is mainly made of chromium alloy, and other alloy components such as manganese, molybdenum, niobium, and nickel are also added. The carbides in the metallographic structure are distributed in a fibrous form, and the fiber direction is perpendicular to the surface. The microhardness of carbide can reach above HV1700-2000, and the surface hardness can reach HRC58-62. Alloy carbide has strong stability at high temperatures, maintains high hardness, and also has good oxidation resistance, and can be used normally within 500°C.

The wear-resistant layer is expressed in narrow channels (2.5-3.5mm), wide channels (8-12mm), curves (S, W), etc.; it is mainly made of chromium alloy, while also adding manganese, molybdenum, niobium, nickel, and boron For other alloy components, the carbides in the metallographic structure are distributed in a fibrous form, and the fiber direction is perpendicular to the surface. The carbide content is 40-60%, the microhardness can reach above HV1700, and the surface hardness can reach HRC58-62.

Wear-resistant steel plates are mainly divided into three categories: general-purpose, impact-resistant and high-temperature-resistant types; the total thickness of wear-resistant steel plates can reach a minimum of 5.5 (2.5+3) mm and a maximum of 30 (15+15) mm; wear-resistant steel plates Wear-resistant pipes with a minimum diameter of DN200 can be rolled and processed into wear-resistant elbows, wear-resistant tees, and wear-resistant reducers.

Hardness, HRC

Wear-resistant layer thickness ≤4mm: HRC54-58;

Wear-resistant layer thickness>4mm: HRC56-62

Appearance parameters

Flatness: 5mm/M

Wear-resistant steel plates have high wear resistance and good impact properties, and can be cut, bent, welded, etc., and can be connected to other structures by welding, plug welding, bolting, etc., which saves time during on-site maintenance. , convenience and other characteristics, it is widely used in metallurgy, coal, cement, electricity, glass, mining, building materials, bricks and other industries. Compared with other materials, it has a high cost performance and has been favored by more and more industries and manufacturers.

RAYIWELL MFG / TOP Metal Materials can supply NM360, BHNM400, BHNM450, BHNM500, BHNM550, BHNM600, BHNM650, NR360, NR400, B-HARD360, B-HARD400 (Origin: Baohua, Wugang, Nangang, Baosteel, Wuhan Iron and Steel, Laigang)

Wear-resistant steel plates are mainly divided into two types: alloy wear-resistant steel plates and composite wear-resistant steel plates. Alloy wear-resistant steel plates are nm400, JFE-EH400, DILLIDUR 400, etc. Composite wear-resistant steel plates are made by surfacing a layer of ordinary steel plates. , make a wear-resistant alloy layer, so it is also called bimetallic wear-resistant steel plate.

NM500 is a high-strength wear-resistant steel plate with high wear resistance and a Brinell hardness value of 500 (HBW). It is mainly used to provide protection in occasions or parts that require wear resistance, making the equipment last longer and reducing maintenance costs.

NM500 wear-resistant steel plate is widely used in engineering machinery, mining machinery, coal mining machinery, environmental protection machinery, metallurgical machinery, abrasive tools, bearings and other product parts.

HARDOX450 wear-resistant steel plate, 450 is a wear-resistant steel plate with a Brinell hardness of 450HB and has good cold bending properties. HARDOX 450 has very good weldability

| Specifications | GB/T24186 abrasion resistant steel plate |

| Standard | GB/T24186 |

| Specialize | Shim Sheet, Perforated Sheet, B. Q. Profile. |

| Length | 50mm-18000mm |

| Width | 50mm-4020mm |

| Thickness | 1.2mm-300mm |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc |

GB/T24186 abrasion resistant steel plate mechanical properties

| Brand | Thickness mm | Tensile Test MPa | Hardness | |||||||

| YS Rel MPa | TS Rm MPa | Elongation % | ||||||||

| NM360 | 10-50 | ≥620 | 725-900 | ≥16 | 320-400 | |||||

| NM400 | 10-50 | ≥620 | 725-900 | ≥16 | 380-460 | |||||

| NM450 | 10-50 | 1250-1370 | 1330-1600 | ≥20 | 410-490 | |||||

| NM500 | 10-50 | — | —- | ≥24 | 480-525 | |||||

| Grade | C | Si | Mn | P | S | Cr | Mo | Ni | Bt |

| NM360 | ≤0.25 | ≤0.70 | ≤1.60 | ≤0.025 | ≤0.015 | ≤0.80 | ≤0.50 | ≤0.50 | 0.0005-0.006 |

| NM400 | ≤0.30 | ≤0.70 | ≤1.60 | ≤0.025 | ≤0.010 | ≤1.00 | ≤0.50 | ≤0.70 | 0.0005-0.006 |

| NM450 | ≤0.35 | ≤0.70 | ≤1.70 | ≤0.025 | ≤0.010 | ≤1.10 | ≤0.55 | ≤0.80 | 0.0005-0.006 |

| NM500 | ≤0.38 | ≤0.70 | ≤1.70 | ≤0.020 | ≤0.010 | ≤1.20 | ≤0.65 | ≤1.00 | 0.0005-0.006 |

| NM550 | ≤0.38 | ≤0.70 | ≤1.70 | ≤0.020 | ≤0.010 | ≤1.20 | ≤0.70 | ≤1.00 | 0.0005-0.006 |

| NM600 | ≤0.45 | ≤0.70 | ≤1.90 | ≤0.020 | ≤0.010 | ≤1.50 | ≤0.80 | ≤1.00 | 0.0005-0.006 |