China Hot dipped Galvanized color coated PPGI steel coil Manufacturer and Supplier | Ruiyi

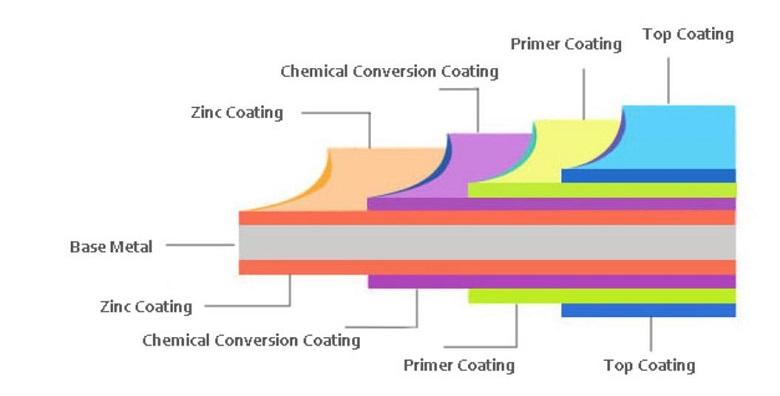

Prepainted galvanized steel coil is a type of steel coil that has been coated with a layer of paint. The paint is typically applied to both sides of the coil using a continuous coil coating process. This coating helps to protect the steel from corrosion and provides an aesthetic finish.

PPGI is pre-painted galvanised iron, also known as pre-coated steel, coil coated steel, color coated steel etc., typically with a hot dip zinc coated steel substrate. The term is an extension of GI which is a traditional abbreviation for Galvanized Iron.

Using Hot Dip Galvanized Steel Coil as the substrate, PPGI is made by first going through surface pretreatment, then the coating of one or more layers of liquid coating by roll coating, and finally baking and cooling. The coatings used including polyester, silicon modified polyester, high-durability, corrosion-resistance and formability.

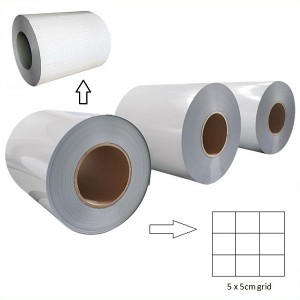

Standard Export Packing:

- 4 eye bands and 4 circumferential bands in steel

- Galvanized metal fluted rings on inner and outer edges

- Galvanized metal and waterproof paper wall protection disk

- Galvanized metal and waterproof paper around circumference and bore protection

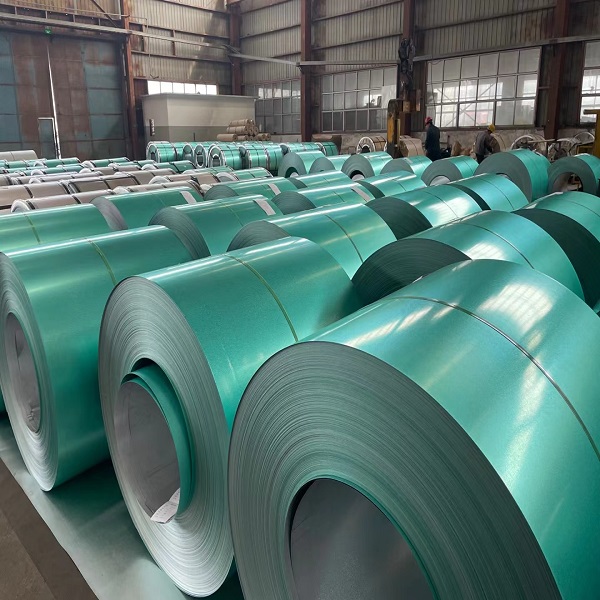

PPGI coil is short for prepainted galvanized steel coil. It is a kind of color-coated steel, which uses hot-dip galvanized steel or electro-galvanized steel (zinc coating) as substrate and is coated with several layers of organic coatings to protect it from rusting. Except for the PPGI steel coil, RAYIWELL / Suzhou Top Metal Materials also has color coated coil using galvalume steel (PPGL) and hot or cold rolled steel as the base metal.

Galvanized Steel Coils is specially designed steel sheets that are employed in several furbishing and manufacturing purposes. Steel coils are thin sheets that can be rolled up into incessant coils. The galvanized coil is employed outdoor, as it shows anti rusting tendencies. Most significantly, it is used in constructing strong roofing system.We also serves its customers with a collection of galvanized steel coils. Our galvanized steel coils are offer in different measurements. We noteworthy range of galvanized steel coils includes hot dipped, aluminum, GL, and galvanized roofing sheet. We reassure our customers with highest quality of steel sheets and coils.

PPGI / PPGL COIL full name is prepainted galvanized / galvalume steel coil, which is painted lacquer on top and bottom side of HDGI / ALU-ZINC coil

| Product Name | PPGI, Prepainted Galvanized Steel Coil |

| Technical Standard | ASTM DIN GB JIS3312 |

| Grade | SGCC SGCD or customer’s requirement |

| Type | Commercial Quality/DQ |

| Thickness | 0.13-2.0mm |

| Width | 600-1500mm |

| Zinc Coating | 40-275 g/m2 |

| Color | all RAL Colors, or According to Customers Require/Sample |

| Top Side | Primer paint+polyester paint coating |

| Back side | Primer epoxy |

| Coil Weight | 3-8 tons per coil |

| Package | Standard export package or customized |

The application of PPGI or prepainted Galvanized steel coil

| Construction | Outside | Workshop, agricultural warehouse, corrugated roof, roller shutter door, drainage pipe |

| Inside | Door, doorcase, light steel roof structure, folding screen | |

| Electrical Appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air condition | |

| Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

| Carrying Trade | Exterior decoration of auto and train, clapboard, container | |

| Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel | |

Color-coated steel coil or steel rolls are lightweight, beautiful and have good anti-corrosion properties, and can be processed directly. The colors are generally divided into gray and white, sea blue and brick red. They are mainly used in the advertising industry, construction industry, home appliance industry, electrical appliance industry, furniture industry and transportation. Industry.

The coating used for color-coated coil selects appropriate resins according to different use environments, such as polyester silicon-modified polyester, polyvinyl chloride plastisol, polyvinylidene chloride, etc. Users can choose according to their usage.

Color-coated steel strips using hot-dip galvanized steel strips as the base material are protected by a zinc layer. The organic coating on the zinc layer plays a covering and protective role to prevent the steel strips from rusting. The service life is longer than that of galvanized strips, about 1.5 times

Hot-dip galvanized base plate

The product obtained by coating organic coatings on hot-dip galvanized steel panels is hot-dip galvanized color-coated panels. In addition to the protective effect of zinc, the hot-dip galvanized color-coated sheet also has an organic coating on the surface that protects and prevents rust, and has a longer service life than hot-dip galvanized sheets. The zinc content of hot-dip galvanized substrates is generally 180g/m2 (double-sided), and the zinc content of hot-dip galvanized substrates for exterior buildings is up to 275g/m2.

Hot dipped aluminum zinc plate

Hot-dip aluminum-zinc steel plate (55% Al-Zn) is used as the new coating substrate, and the aluminum-zinc content is usually 150g/㎡ (double-sided). The corrosion resistance of hot-dip galvanized sheets is 2-5 times that of hot-dip galvanized sheets. Continuous or intermittent use at temperatures up to 490°C will not cause serious oxidation or scale. The ability to reflect heat and light is twice that of hot-dip galvanized steel, and the reflectivity is greater than 0.75, making it an ideal building material for energy saving.

Electroplated zinc base plate

The product obtained by using an electro-galvanized sheet as the substrate, coating it with organic paint and baking it is an electro-galvanized color-coated panel. Since the zinc layer of the electro-galvanized sheet is thin and the zinc content is usually 20/20g/m2, this product is not suitable for use. Make walls, roofs, etc. outdoors. However, due to its beautiful appearance and excellent processing properties, it can be mainly used in home appliances, audio, steel furniture, interior decoration, etc.