China High glossy refective Specular bright alloy 1085 anodized aluminum mirror finish sheet Manufacturer and Supplier | Ruiyi

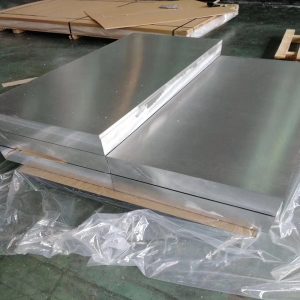

Anodized aluminum sheet is a sheet metal product consisting of aluminum sheeting exposed to an electrolytic passivation process that imparts a tough, hard-wearing protective finish on its surface. The protective layer formed by the anodizing process is actually little more than an enhancement of the natural oxide layer that exists naturally on the surface of the aluminum.

The aluminum plate of the anode is oxidized, and a thin layer of aluminum oxide is formed on the surface, the thickness of which is 5-20 microns, and the hard anodized film can reach 60-200 microns. The anodized aluminum plate has improved its hardness and abrasion resistance, up to 250-500 kg / mm2, good heat resistance, hard anodized film melting point up to 2320K, excellent insulation, and breakdown voltage 2000V, which has enhanced the anti-corrosion performance. It will not corrode for thousands of hours in ω = 0.03NaCl salt spray. There are a large number of micropores in the thin layer of the oxide film, which can absorb various lubricants, which is suitable for manufacturing engine cylinders or other wear-resistant parts.

Anodized aluminum plate is widely used in machinery parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine housing, lighting, consumer electronics, crafts, household appliances, interior decoration, signage, furniture, automotive decoration and other industries

Anodized aluminum is created through an electro chemical process which allows the color to penetrate the pores of the aluminum, resulting in an actual change in the color of the metal surface. Anodized aluminum is harder and more resistant to abrasion and corrosion.

The main products of mirror finish aluminum sheet are 1 series of 1050 Mirror finish aluminum sheet, 1060 alloy aluminum plate, 1070 alloy aluminum plate, 1100 alloy aluminum plate; 3 series of 3003 aluminum plate, 3004 aluminum plate, 3005 aluminum plate, 3104 alloy aluminum plate, 3105 alloy aluminum plate; 5 series of 5182 aluminum plate and 5052 aluminum alloy, as well as the rare 8 series 8011 aluminum plate, the material state is mainly O, H * 2, H * 4, H18, H19, and the thickness is 0.1-6.0mm. As mirror finish aluminum sheet manufacturer and supplier, the reflection rate of mirror finish aluminum sheet produced by RuiYi Aluminum Co., Ltd. can reach 85% -88%