-

soft forming quality Electro hot dip galvanized steel plate SECC JIS G 3313 Electro-Galvanized Commercial Cold Rolled

soft forming quality Electro hot dip galvanized steel plate SECC JIS G 3313 Electro-Galvanized Commercial Cold Rolled

Electro Galvanized Steel(EGI) EGI is made in the way of electro galvanizing zinc over cold rolled steel. This product with high corrosion resistance has less coating than GI steel but features even coating thickness, good surface, and coating at a low temperature

SECC steel is electro-galvanized commercial quality cold rolled steel which is basically cold rolled and then coated with zinc in an electro-galvanizing line. SECC is a material grade and designation defined in JIS G 3313 standard. It is a low-cost steel metal grade with improved thermal conduction that is mostly utilized for the casings of computer and other electronic accessories. As a basic Zinc-Coated Carbon Steel it can be enumerated in mild steel which is processed under electro galvanization, unlike the SGCC steel which is processed hot-dip galvanized steel.

The based metal is actually made up of commercial quality cold rolled steel but the coating is made up of zinc through electro galvanization process unlike the hot-dip galvanized steels. Following forming operations can be performed on this type of steel:

- Pressing

- Blanking

- Shaping

- Lancing

- Piercing

- Notching

- Stamping

However, any specific forming operation should be properly investigated and testing should be performed before the execution.

Following are the available forms of SECC steels in the global market:

- Galvanized Coils

- Slit Edge Galvanized Coils

- Cut to Length Galvanized Sheets

-

SECC DX51D 0.31mm Zinc Coated Steel Sheet HDGI Coil Hot Dipped Galvanized Steel Coil

GI/SECC DX51D 0.31mm Zinc Coated Steel Sheet HDGI Coil Hot Dipped Galvanized Steel Coil

SECC steel is electro-galvanized commercial quality cold rolled steel which is basically cold rolled and then coated with zinc in an electro-galvanizing line. SECC is a material grade and designation defined in JIS G 3313 standard.

SECC is a stamping material, which is coated with a zinc layer on the surface of the cold-rolled sheet. Rust and corrosion-resistant. The price is relatively high. The general board thickness is 0.4~3.2mm.

Applicable grades of Japanese electro-galvanized steel sheet: SECC (original plate SPCC), SECD (original plate SPCD), SECE (original plate SPCE) Zinc layer code: E8, E16, E24, E32 Symbol: S-steel (Steel), E-plating (Electrodeposition) ), C-cold rolled (Cold), the fourth C-common grade (common).

ProductGalvanized steel coil(Gi Coil)Width1000mm/1219mm/1240mm/1500mm/2000mm or as customer’s requirementsThicknessCold rolled:0.1~4.0mmHot rolled:4mm~100mmLength100mm to 12000mm or as customer’s requestZinc coating60g/m²-275g/m²-GradeSPCC,SPCD,SPCE,ST12-15,DC01-06,Q195A-Q235A,Q195AF-Q235AF,

Q295A(B)-Q345A(B)StandardsAISI ASTM JIS SUS DIN GBCertificationsISO 9001PackingIndustry standard packaging or according to client’s requirement -

S350GD G550 dx51d dx52d z150 z140 steel building galvanized steel coils sheets DX51D Slit Coil

Galvanized Steel Sheet is defined as a carbon steel sheet coated with zinc on both sides. Galvanized Steel Coil produce galvanized steel with two main processes: continuous hot dip galvanizing and electro galvanizing.

Specifications of Galvanized Steel Coils that We Can Provide :

1) Standard: JIS G3302 1998, ASTM A653M/A924M 2004, all according to the customer’s request

2) Grade: SGCC, SGCH,DX51D, Q195,Q235 all according to the customer’s request3) Capacity: about 12000 tons per month

4) Thickness: from 0.13mm to 2mm, all available

5) Width: from 600mm to 1250mm, regular size:750-762mm,900-914mm,1000mm,1200mm,1219-1250mm all available

6) Coil ID: 508mm

7) Coil weight: from 2-10MT, according to the customer’s request

8) Zinc coating weight: 40g/m2-275g/m2

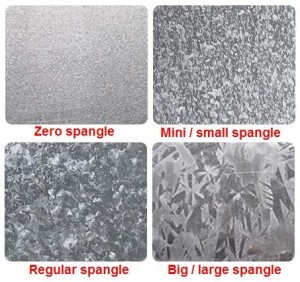

9) Spangle: regular spangle,big spangle, small spangle and zero spangle

10) Surface treatment: Chemical passivating, oils, passivating oils,skin passed

11) Edge: mill edge, cut edge

12) Min trial order 25 ton each thickness -

China Prime G30 G60 G90 Hot Dipped Galvanized Steel Coil/ Gi Steel Coil / HDG Zinc Coating Roll Manufacturer

China Prime G30 G60 G90 Hot Dipped Galvanized Steel Coil/ Gi Steel Coil / HDG Zinc Coating Roll Manufacturer

Name Galvanized steel coil Grade DX51D+Z, DX52D+Z, DX53D+Z, DX54D+Z, DX56D+Z, DX57D+Z, DC51D+Z, SGCC, SGCD,S220GD+Z, S250GD+Z, S280GD+Z, S320GD+Z, S350GD+Z, S550GD+Z Width 600-1500mm Thickness 0.12-4mm Zinc coating 30-275/m2 Surface treatment chromed / oiled/slightly oiled/ dry Hardness soft, full hard, half hard Spangle zero spangle / minimized spangle / regular spangle/ big spangle ID coil 508mm or 610mm Coil weight 2-8 MT per coil. According to the customer’s requirements Package: Standard export package (Plastic film in the first layer,second layer is Kraft paper. Third layer is galvanized sheet) Application: Industrial panels, roofing and siding for painting Applications of Our Galvanized Steel Coils :

1.Construction and building: roofing; ventilating duct; handrail; partition panel,etc.

2.Further processing: coating base plate.

3.Electric appliance: refrigerator; washing machine; recorder; microwave, etc.The hot dip process includes passing the steel through a molten zinc bath, and the electro galvanizing process includes applying zinc through electrolytic treatment. As a result, the zinc layer is firmly adhered to the base metal through the iron-zinc bonding layer. Our hot-dip galvanized products are manufactured in accordance with specifications, and our electro-galvanized products comply with the specifications.

Galvanizing is one of the most effective and economical methods for protecting bare steel from corrosive environments. Zinc is not only a barrier between steel and the environment, but also sacrifices itself to protect the steel plate below. When two different metals are in contact and coupled with water and oxygen, sacrifice or current protection occurs. Zinc preferentially corrodes iron in steel. This protection prevents corrosion of the steel in areas not covered by zinc. Therefore, the diffusion of corrosion from cutting edges, drilling holes, etc

-

ASTM 653 Prepainted PPGL DX51D DX52D SGCC Galvanized Steel Sheet Coil

Galvanized steel is a hot-dipped coated metal that provides customers with better resistance to corrosive environments.

To create galvanized steel, cold rolled steel is submerged into a molten zinc bath, known as the hot-dip process (galvanization can also be achieved through continuous galvanizing). When the material is removed from the zinc bath and cooled a reaction to the oxygen in the air occurs. The reaction causes the zinc coating to become part of the steel creating the well-recognized spangled finish.

Specification Product Name Galvanized Steel Coil Brand RAYIWELL MFG/ BAOSTEEL Thickness 0.12mm-6mm Width 600mm-1250mm or Customized Surface Galvanized Coated / Zinc coating Zinc Coating 15-275g/m2 Paint PE PVDF SMP HDP Product Capacity 60000Ton/Year Hot-Dip Galvanized Steel Coil has excellent performance, possessing ideal comprehensive properties of corrosion resistance, formation and coating. It is produced by passing the steel sheet which has undergone the acid washing process and rolling process through the zinc pot, thereby applying zinc film to the surface. It has excellent corrosion resistance, paintability, and workability due to Zinc’s characteristic

-

Anti-Fingerprint (AFP) SGCC SGCH Hot Dipped GI Coil DX51D-56D Galvanized Steel Coil

Anti-Fingerprint (AFP) SGCC SGCH Hot Dipped GI Coil DX51D-56D Galvanized Steel Coil

The anti-fingerprint effect means that fingerprints on the surface cannot be seen at all by the naked eye, or only very slightly. Although the fingerprint is actually on the surface, it is essentially “invisible“.

product Galvanized Steel Coil material Q195/Q235/Q235B/Q345/Q345B/SS400/DC01-04/DX51D-56D/SGCC SGCH Thickness 0.12 ~ 3.00 mm (cold rolled)

1.20 ~ 4.60 mm (Hot-rolled )Width 10 – 600 mm (strip)

600 – 1250 mm (coil)Color Plain Surface Treatment Galvanized Coated, Anti-Fingerprint (AFP) Grade DX51D,DX52D,DX53D SGCC SGCH Standard AISI ASTM BS DIN GB JIS Tolerance ±1% Technique Cold rolled or Hot rolled Application Widely used in road, railway,

civil construction, water conservancy construction; all kinds of machinery, electrical appliances,window protection and aquaculture, etc.Processing Service Bending, Welding, Decoiling, Cutting, Punching Coil ID 508mm or 610mm Coil weight 3 – 8 ton or as client requirement Zinc coating 30g – 275g / m2 Spangle Big spangle,Regular spangle,Mini spangle,Zero spangle Galvanized steel coil, immersing the thin steel plate in the molten zinc bath, and adhering a layer of zinc thin steel plate on the surface. Galvanised steel coil is mainly produced by the continuous galvanizing process, that is, the coiled steel plate is continuously immersed in the zinc-melted plating tank to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also made by the hot-dip method, but it is heated to about 500 °C immediately after exiting the tank to form an alloy film of zinc and iron. This galvanized steel coil has good paint adhesion and weldability.

Galvanised steel coil application:

1. Buildings And Constructions

Floor Decks, Ceilings, Duct Work, Roofing, Siding, Sashes, Beams, Fences, Verandas, Shutters, Awnings,

Partitions, Indoor Decorations, Pipes, Ventilators, Sheds, Culverts.

2. Transportation

Body Pane, Air Cleaners, Oil Filters, Fuel Tanks, Containers, Highway Barriers.

3. Appliances

Light Fittings, Washing Machines, Dryers, Coolers, Vending Machines, Water Heaters, Stoves, Refrigerators, Freezers, Tool Boxes.

4. Agriculture

Barns, Dryer Panels, Animal Houses, Hoppers. Bar Supporters, Irrigation Systems, Green Houses.

-

Galvanized Steel Coil Sheets DC51D+Z DC51+ZF DD51D+Z DC52D+Z DC52D+ZF DC51D+AZ

Galvanized Steel Sheet is defined as a carbon steel sheet coated with zinc on both sides. Galvanized Steel Coil produce galvanized steel with two main processes: continuous hot dip galvanizing and electro galvanizing.

Specifications of Galvanized Steel Coils that We Can Provide :

1) Standard: JIS G3302 1998, ASTM A653M/A924M 2004, all according to the customer’s request

2) Grade: SGCC, SGCH,DX51D, Q195,Q235 all according to the customer’s request3) Capacity: about 12000 tons per month

4) Thickness: from 0.13mm to 2mm, all available

5) Width: from 600mm to 1250mm, regular size:750-762mm,900-914mm,1000mm,1200mm,1219-1250mm all available

6) Coil ID: 508mm

7) Coil weight: from 2-10MT, according to the customer’s request

8) Zinc coating weight: 40g/m2-275g/m2

9) Spangle: regular spangle,big spangle, small spangle and zero spangle

10) Surface treatment: Chemical passivating, oils, passivating oils,skin passed

11) Edge: mill edge, cut edge

12) Min trial order 25 ton each thicknessApplications of Our Galvanized Steel Coils :

1.Construction and building: roofing; ventilating duct; handrail; partition panel,etc.

2.Further processing: coating base plate.

3.Electric appliance: refrigerator; washing machine; recorder; microwave, etc.The hot dip process includes passing the steel through a molten zinc bath, and the electro galvanizing process includes applying zinc through electrolytic treatment. As a result, the zinc layer is firmly adhered to the base metal through the iron-zinc bonding layer. Our hot-dip galvanized products are manufactured in accordance with specifications, and our electro-galvanized products comply with the specifications.

Galvanizing is one of the most effective and economical methods for protecting bare steel from corrosive environments. Zinc is not only a barrier between steel and the environment, but also sacrifices itself to protect the steel plate below. When two different metals are in contact and coupled with water and oxygen, sacrifice or current protection occurs. Zinc preferentially corrodes iron in steel. This protection prevents corrosion of the steel in areas not covered by zinc. Therefore, the diffusion of corrosion from cutting edges, drilling holes, etc

-

silicon steel coil

Electrical steel is mainly divided into GO electrical steel and NGO electrical steel two categories.Easy magnetization direction of GO electrical steel distribution along the rolling direction, the direction of rolling with high induction, excellent characteristics such as low iron loss and low magnetostriction, while the magnetic domain refinement processing technology, lower iron loss of performance, and are widely used in the transformer industry.

Product Description:

1.Grain-Oriented Electrical Steel

- Thickness:0.23mm,0.27mm,0.30mm,0.35mm

- Width: 900-1200mm

- Inner Diameter: 508mm

2.Non-Oriented Electrical Steel

- Thickness:0.20mm,0.35mm,0.50mm,0.65mm

- Width: 800-1250mm

- Inner Diameter: 508mm

We supply to silicon steel scrap,silicon steel coil, silicon steel sheet,silicon steel,silicon steel plate,silicon steel,cold-rolled non grain oriented silicon steel coil,silicon coil, silicon steel coils,Grain Oriented Silicon Steel,Electrical Steel Coils, Grain Oriented Silicon Electrical Steel,Electrical steel,Silicon steel,Magnetic Steel, Grain-Oriented Electrical Steel, oriented electrical steel,Grain Oriented Silicon Steels,Grain Oriented Flat-rolled Electrical Steel,rolled Electrical Steel, Non-Oriented Electrical Steel,Oriented Electrical Steel,Non-oriented Silicon Steel, CRNGO, GO Electrical Steel, high induction GO Electrical Steel, NSGO, domain refined NSGO, NGO electrical steel, Common GO electrical steel, High induction GO electical steel, High induction GO electical steel,etc.

-

Hot dipped Regular Spangle Galvanized Steel Coil G350 z600

Regular Spangle Galvanized Steel Coil G350 z600/GI/HDGI/Galvanised steel/Galvanized coils

HGI/GI/Hot dip Galvnaized steel coil/Galvanized steel coil G550 z275/zinc steel/steel coil/zinc steel coil/Hot dip zinc steel coil/Regular Spangle Galvanized Steel Coil G350 z600

Product Description:

- Product Description:GI COIL,GI SHEET, GI PLATES DX 51D/SGCC,G350,G550

- Product Name: Hot dip galvanized steel coil /Galvanzied steel Coil/HDGI/GI /GI Coil /GI sheet

- Base Metal:cold rolled steel coil

- Spangle:zero spangle, regular spangle,mini spangle,big spangle

- Thickness: from 0.15mm to 5.0 mm

- Width:from 600mm to 1500 mm

- Standard:AISI,ASTM653,BS,DIN,JIS3302,GB

- Grade:DX51D,DX52D/DX53D/DX54D, S350, S400,S450, S550, G550,SGCC,G350ST01Z,CSA,CSB,FSA,FSB,DDS

- Zinc coating:From z60g/m2 to z600g/m2 , z60g/m2,z80g/m2,z90g/m2,z100g/m2, z120g/m2,z140g/m2, z150g/m2, z160g/m2, z180g/m2, z200g/m2,z250g/m2, z275g/m2, z300g/m2, z400g/m2, z500g/m2, z600g/m2

- Minimum order quantity:20 ton for each size.

- Certification:ISO9001, SGS

- Payment terms: TT or LC at sight.

- Application:Building field;Home appliances;Automatic Industry

-

SGCC JIS G3302 Galvanized steel coil sheet manufacturer

Galvanized steel coil, immersing the thin steel plate in the molten zinc bath, and adhering a layer of zinc thin steel plate on the surface. This kind of steel plate is also made by the hot-dip method, but it is heated to about 500 °C immediately after exiting the tank to form an alloy film of zinc and iron.

Galvanized steel is used to make corrosion-resistant nuts, bolts, and nails. It’s used for outdoor pipes when plastic piping is not strong enough. It’s used for bus stop benches, balconies, verandas, staircases, walkways, and ladders.

Product name Galvanized Steel Coil Material ASTM A653, DX51D, Q195 Zinc Coating 20-275g/m2 Thickness 0.13-0.8 mm / custom Width 600-1250 mm /custom