China UNS T30407 ASTM A681 forged cold work D7 Tool Steel bar Manufacturer and Supplier | Ruiyi

Hot forging die steel D7 is a commonly used die steel, and its main components are carbon (C), chromium (Cr), molybdenum (Mo), manganese (Mn) and silicon (Si). Its chemical composition and mechanical properties are as follows:

chemical composition:

– Carbon (C): 1.40-1.60%

– Chromium (Cr): 11.00-13.00%

– Molybdenum (Mo): 0.50-1.10%

– Manganese (Mn): 0.20-0.60%

– Silicon (Si): 0.10-0.40%

Mechanical behavior:

– Tensile strength: ≥1275 MPa

– Yield strength: ≥1120 MPa

– Elongation: ≥15%

– Hardness: ≥321 HB

Hot forging die steel D7 has high hardness, high strength, good wear resistance and thermal stability, and is suitable for manufacturing molds, stamping tools, cutting tools and other tools and parts that require high strength and wear resistance.

| Product type | Products | Dimension | Processes | Deliver Status |

|---|---|---|---|---|

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

D7 die steel is a high-carbon high-chromium cold work tool steel with excellent wear resistance, hardness and heat resistance, and is suitable for manufacturing various molds and tools. The following are some of the main uses of D7 tool steel:

1. Manufacturing stamping dies: D7 die steel has high hardness and wear resistance, and is suitable for manufacturing stamping dies, such as punches and punch seats.

2. Manufacturing cutting tools: The hardness and wear resistance of D7 mold steel make it an ideal material for manufacturing cutting tools, such as knives, milling cutters, drills, etc.

3. Manufacturing cold working dies: D7 die steel has excellent wear resistance and impact resistance, and is suitable for manufacturing cold working dies, such as blanking dies, bending dies, etc.

4. Manufacture of hot work dies: D7 die steel has high heat resistance and is suitable for manufacturing hot work dies, such as hot pressing dies, hot molding dies, etc.

5. Manufacture of plastic molds: D7 mold steel has good wear resistance and corrosion resistance, and is suitable for making plastic molds, such as injection molds, extrusion molds, etc.

Due to its excellent hardness, wear resistance and heat resistance, D7 die steel is widely used in the die manufacturing industry to manufacture various types of dies and tools to improve production efficiency and product quality.

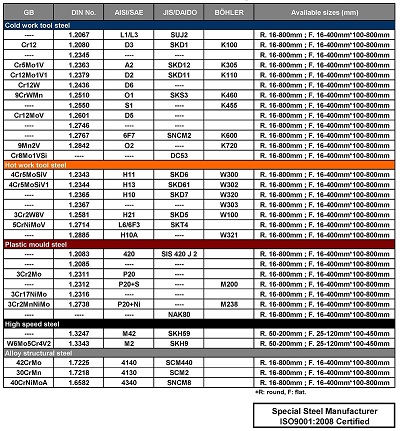

RAYIWELL can offer other Hot work or cold work tool steel flat bar or round bar as follows, we welcome custom order as well