China Customized 6061 6101 Alloy Aluminium Sheet for Vehicles Molds Parts Manufacturer and Supplier | Ruiyi

The 6061 alloy is one of the most common for extrusion, but you may be considering other options for your particular application. Below are some other common alloys that are often considered as alternatives.

6061 and 6063 are the two most popular extrusion alloys. 6063 aluminum occupies the number one spot and 6061 occupies spot number two. As alloys in the 6000 series, they both have magnesium and silicon as their primary alloying elements. Thus, they have many similar properties. 6061 offers higher strength, however. As such, it is often used for more structural applications. 6063, on the other hand, is used for applications such as railing or trim, windows, and doors, due to its better appearance and corrosion resistance.

Like 6061, 5052 aluminum has magnesium as a primary alloying element. In the case of 5052, it is the only primary alloying element. 6061 has silicon as well. One of the key benefits of this alloy is its high level of weldability compared to other alloys. For projects where weldability is key, it is worth considering. One downside to 5052, though, is that it is not heat treatable. It is good for a variety of welding applications and it works well in marine applications due to its high corrosion resistance.

Primarily used in aerospace applications, the 2024 alloy is known for high strength. Its main alloying element is copper, and although it is strong and has good fatigue resistance, it is less machinable and more difficult to weld than 6061. It also offers poor corrosion resistance and is often used in wing and fuselage structures which come under high tension.

Alloy 6061 displays good tensile strength, which can be improved by temper treatment, and good corrosion resistance, weldability, and workability. Its workability makes it the right choice for many extrusion projects, as it is easy to form.

The alloy is widely available at a relatively low cost and is a great option to produce varied and precise components in different shapes. Although alloy 6061 doesn’t rank first in any aluminum properties tier list, it’s a great and reliable all-around aluminum alloy to work with

A member of the 6000 series, 6061 aluminum’s main alloying elements are magnesium and silicon, and it’s a great example of a jack of all trades. The alloy is somewhat universal, seeing some exposure in structural and building products as well as the aerospace and recreation industries.

Alloy 6061 displays good tensile strength, which can be improved by temper treatment, and good corrosion resistance, weldability, and workability. Its workability makes it the right choice for many extrusion projects, as it is easy to form.

The alloy is widely available at a relatively low cost and is a great option to produce varied and precise components in different shapes. Although alloy 6061 doesn’t rank first in any aluminum properties tier list, it’s a great and reliable all-around aluminum alloy to work with

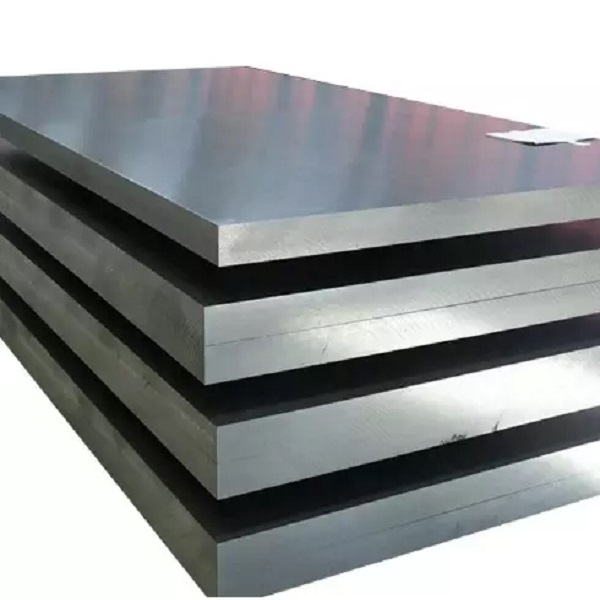

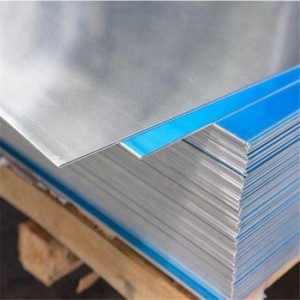

- Al metal alloy: 6061 grade

- Alu temper: T6

- Width: 100mm-2850

- Thickness: 0.4mm – 300mm

- Hot size: 4×8,5×10,1000 x 2000mm, 1250mm x 2500mm or customized size.

- Used: Mobile phone shell, mobile phone board, card slot

- Technology: hot rolled ( DC ), cold rolling ( CC ), cast

- Standard: ASTM B209, GB/T 3880, EN AW, DIN, MSRR, AMS, JIS, AISI, BS, etc

- Custom service: acceptable ( OEM, ODM, etc )

- Port of Loading: Qingdao, Shanghai, Guangzhou, etc China main port

- Certifications: GB/T19001-2016/ISO9001:2021, CE, SGS etc