China Shipping Building 5082 5083 7075 3003 Aluminum Sheet Plate Coil Manufacturer and Supplier | Ruiyi

5083 aluminium sheet also has very good welding performance. According to ESAB (a major international welding equipment manufacturer), compared with other aluminum alloys, 5083 will only lose 7% of its tensile strength around the welding zone, and 5052 will lose 19%~36% after welding. Heat-treated alloys such as 6061 may lose about 80% of the tensile strength around the heat-affected zone of the weld bead

these 5083 aluminum sheets are hardened to an H131 temper for increased strength and impact resistance over standard 5083 sheets. They meet MIL-DTL-46027 and are the grade of aluminum used for personnel carriers in military operations. 5083 is highly corrosion resistant and is especially suited for use around salt water

Temper: F, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H111, H112, H114

Thickness:0.2-350mm

Width:30-2600mm

Length:200-11000mm

Mother coil: CC or DC

Weight: About 2mt per pallet for general size

MOQ: 5-10ton per size

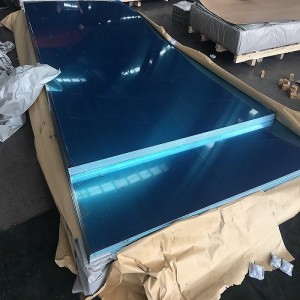

Protection: paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement.

Surface: clean and smooth, no bright speck, corrosion, oil, slotted, etc.

Standard product: GBT3880, JIS4000, EN485, ASTM-B209, EN573

Delivery time: about 30days after receiving the deposit

Payment: T/T, L/C at sight

Trading terms: FOB, CIF, CFR

Aluminium 5083 is used in Shipbuilding, Rail cars, Vehicle bodies, Tip truck bodies, Mine skips and cages, Pressure vessels, Marine and drilling rigs