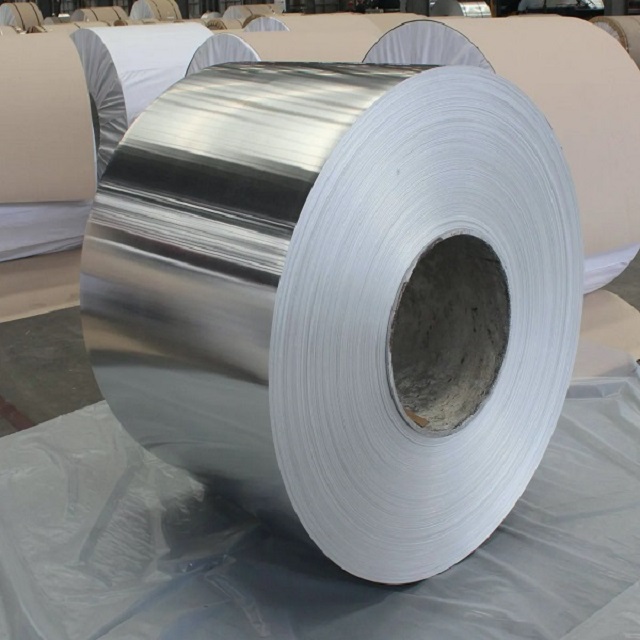

China 6061 aluminum coil manufacturer Manufacturer and Supplier | Ruiyi

6061 Aluminum Plate is an aluminum-silicon-magnesium alloy, strengthened by precipitation hardening. 6061 aluminum coil has medium strength, formability, weldability, machinability and corrosion resistance.

One of the more versatile out of the heat-treated alloy 6061 aluminum coil commonly is used for flooring, ramps, and stairs due to its toughness and great corrosion resistance.

Aluminum coil 6061 T6 temper has an ultimate tensile strength of at least 42,000 psi (290 MPa) and yield strength of at least 35,000 psi (241 MPa). In thicknesses of 0.250 inch (6.35 mm) or less, it has elongation of 8% or more; in thicker sections, it has elongation of 10%. T651 temper has similar mechanical properties.

Alloy 6061 alumium plate has a relatively high strength, easily welded and is widely used not only for making bicycle frames, but also in construction, aircraft, shipbuilding.

The main alloying elements in 6061 aluminum plate are magnesium and silicon, with moderate strength, good corrosion resistance, weldability and oxidation effect. Widely used in various industrial structures requiring certain strength and high antibiotic corrosion resistance.

The main chemical components are: copper 0.15-0.4%, silicon 0.4-0.8%, iron 0.7%, manganese 0.15%, magnesium 0.8-1.2%, zinc 0.25%, chromium 0.04-0.35%, titanium 0.15%.

The difference between 6061 aluminum plate T6 and T651 is that, under normal circumstances, the internal stress of T6 will be relatively large, and it will be deformed during processing. The most suitable state for processing should be T651, stretched on the basis of T6, and eliminate internal stress.

6061-T6 : cooling after solution heat treatment to achieve high strength, no cold working;

6061-T651 : Cooling after solution heat treatment to achieve high strength, and then cold stretching by stretching machine to eliminate residual internal stress after heat treatment, so as to ensure the precision of machined products without deformation after deep processing.

6061 T6 Aluminum coil is a commonly used aluminum alloy. Unless otherwise specified, it is generally in the 6061 T6, and 6061 T651 is the best feature of the 6-series aluminum alloy, and it is a fighter in the 6000-series aluminum alloy. It has excellent processing performance, excellent welding characteristics and electroplating performance, good corrosion resistance, high toughness, no deformation after processing, dense material without defects, easy polishing, easy coloring and film formation and excellent oxidation effect.

Since 6061-T651 is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process, although its strength cannot be compared with 2XXX series or 7XXX series, it has many characteristics of magnesium and silicon alloys, excellent processing performance and excellent welding Features and electroplating, good corrosion resistance, high toughness and no deformation after processing, compact material without defects and east to polish, easy to color film, excellent oxidation effect and other excellent characteristics. The representative applications of 6061-T651 include aerospace fixtures, electrical fixtures, and communication fields, and are also widely used in automated mechanical parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC board solder carriers, etc.

The states of 6061 aluminum plates are O state, T4, T6, T651, etc. For different states, the application fields are different. 6061 aluminum plate has high strength, good anti-corrosion and anti-oxidation effects, and is widely used in automatic mechanical parts, precision machining, automobile chassis, cake molds, etc., and is deeply loved by users.

Both the 6061-T6 aluminum plate and the 6061-T651 aluminum plate are commonly used. The difference between the T6 state of the 6061 aluminum plate and the T651 is:

The internal pressure of T6 is high, and the processing deformation is more suitable for processing. The state is T651, which eliminates internal stress on the basis of T6 extension. The main alloy elements of 6061 aluminum plate are magnesium and silicon, which have medium strength, high strength, weldability and good oxidation effect.

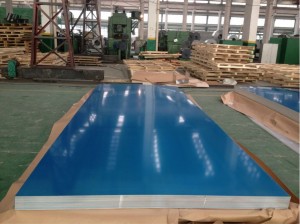

Temper: T1,T2,T3, T4, T6, T651

Thickness:0.2-350mm

Width:30-2600mm

Length:200-11000mm

Mother coil: CC or DC

Weight: About 2mt per pallet for general size

MOQ: 5-10ton per size

Protection: paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement.

Surface: clean and smooth, no bright speck, corrosion, oil, slotted, etc.

Standard product: GBT3880, JIS4000, EN485, ASTM-B209, EN573

Delivery time: about 30days after receiving the deposit

Payment: T/T, L/C at sight

Trading terms: FOB, CIF, CFR