China 1050 aluminum coils Manufacturer and Supplier | Ruiyi

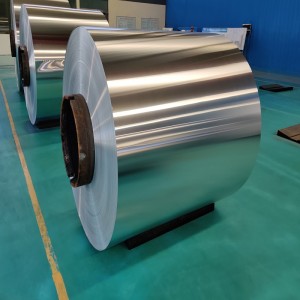

1050 aluminum coils is divided into cold-rolled and hot-rolled, cost-effective, 1050 aluminum coil has high plasticity, corrosion resistance, good electrical and thermal conductivity characteristics, but the strength is low, suitable for the requirements of corrosion resistance and formability are high occasions, chemical equipment is a more typical use.

1050 aluminum coils is commonly used in the electrical and chemical industries, on account of having high electrical conductivity,corrosion resistance and workability.

Aluminum coils 1050 is also sometimes used for the manufacturer of heating sinks, since it has a higher thermal conductivity than any other alloys.

Aluminum as one of most important metals is widely used in industry and our daily life, when it comes to the aluminum alloy, the 1000 series aluminum sheet come to our mind, there are two typical aluminum sheets in 1000 series aluminum sheet alloy, which are 1050 and 1060 aluminum, these two-aluminum alloy are somewhere looks same but they have different content.

1050 aluminum sheet and 1060 aluminum sheet are all belongs to 1000 series pure aluminum sheet, the aluminum content of them is all up to 99%, the difference is that to 1050 aluminum sheet, the content is 99.5%, while to 1060 aluminum sheet, the content is 99.6%, in other words, the aluminum content of 1060 aluminum sheet is a little higher than 1050 aluminum sheet

But in general, the chemical composition and the physical property of them are similar, so they can replace each other, nowadays, 1060 aluminum sheet are used in industry application instead of 1050 aluminum sheet.

Temper: F, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H111, H112, H114

Thickness:0.2-350mm

Width:100-2600mm

Length:200-11000mm

Mother coil: CC or DC

Weight: About 2mt per pallet for general size

MOQ: 5ton per size

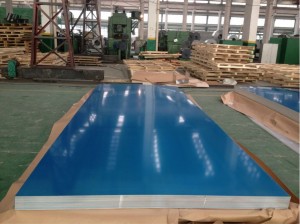

Protection: paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement.

Surface: clean and smooth, no bright speck, corrosion, oil, slotted, etc.

Standard product: GBT3880, JIS4000, EN485, ASTM-B209

Delivery time: about 30days after receiving the deposit

Payment: T/T, L/C at sight

Trading terms: FOB, CIF, CFR

1050 is the most common standard aluminium grade. It has good mechanical properties and like all aluminium is less than a third of the mass of steel. Alloy 1050 offers good corrosion resistance and is readily fabricated. Aluminium is an excellent conductor of heat and electricity.

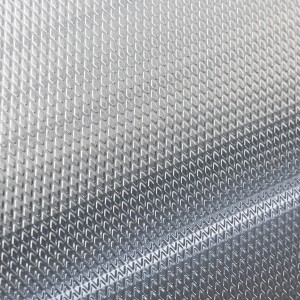

1050A alloy has excellent corrosion resistance, high ductility, a moderate strength and a highly reflective finish. This grade of alloy is most suitable of use as food industrial containers, architectural flashings, cable sheathings, lamp reflectors and chemical process plant equipment.

Grade 1050A has superior anodizing properties for both decorative and technical requirements. It is also well-suited to chemical and electrolytic brightening.