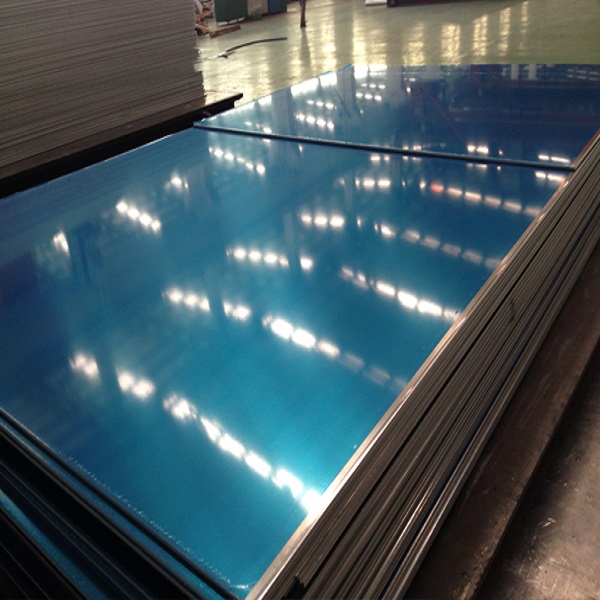

China Good Formability 3003 H22 H14 5052 Aluminium Metal Plates 1100 Flat Aluminum Sheet Plate Manufacturer and Supplier | Ruiyi

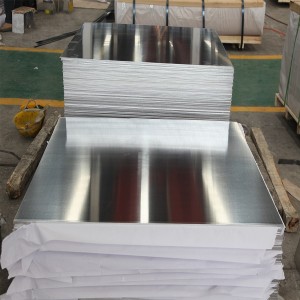

Good Form-ability 3003 H22 H14 aluminum sheet 5052 aluminium metal plates 1100 flat aluminum sheet plate

3003 aluminum sheet Designed for sheet metal work, fuel tanks, and other applications that require a slightly higher strength than 1100 series aluminum.

The 3003 aluminum sheet is a pure aluminum that is used commercially. It’s moderately strong and can resist corrosion. Although it’s not heat treatable, it can be easily welded. It can also be formed using hot working and cold working methods. It is one of the alloys that have great machinability. When being forged with heat, it’s best for the temperature to range between 950 degrees and 500 degrees Fahrenheit. It’s best to use a filler rod like the AL 4043 when welding together 3003 aluminum with alloys like 5052, 6062 and 6061.

This aluminum grade can also be easily cold worked and has annealing capabilities, which should be done at 775 degrees Fahrenheit either during or after cold working. Afterward, air cooling should be allowed. The conductivity of 3003 alloys is 40 percent of copper.

The reason this metal is widely used is because it is affordable and strong. Compared to the 1100 series of alloys, 3003 aluminum is 20 percent stronger. This is due to it being integrated with 1.20 percent manganese. It is considered a pure aluminum and is frequently used in various applications, such as for storage tanks, tool boxes, walkways, truck beds, decorative trim and chemical equipment. It can also be used to create fan blades, siding, trailer components, kitchen equipment, cooking utensils and for signage applications.

3003 aluminum has a lot of great characteristics that make it a popular choice. Other than being weldable and corrosion-resistant, it also has a surface that has a highly polished finish, making it an attractive choice. Although thin, it cannot be bent easily, instead requiring special tools to do so

Aluminum alloy plate Sheet 3003 H14 Bare is an excellent choice for chemical equipment and general sheet metal projects due to its superior corrosion resistance and good workability. Aluminum 3003 H14 bare sheet works well in fabrication and decorative architectural uses because it is highly workable, formable, and weldable, while being capable of withstanding outdoor weather

Alloy 3003 is fairly low strength but it can be hardened to a significant degree by cold working, enabling a series of “H” tempers. Alloy 3003 is also produced as a bright finish treadplate (also known as chequer plate) with industrial and decorative applications.

3003-H14 Aluminum alloy plate is alloyed with 1.20% manganese, which increases the strength of 3003 over commercially pure aluminum (1100 series).3003 has excellent workability, weldability, and good corrosion resistance

3003 Aluminum is one of the most widely used of all aluminum alloys. It is a general purpose aluminum, with moderate strength, good workability and weldability, and excellent corrosion resistance. 3003 is a non heat treatable grade, and it may be deep drawn, or spun, welded, or brazed.

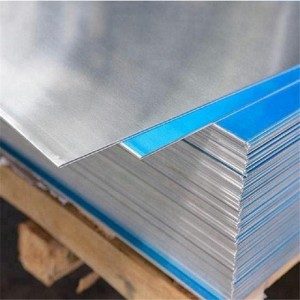

Alloy Available: 1050 1060 1100 3003, 3105, 5052, 5005, 5754 5083 5182, 6061 6063 6082, 7075, 8011…

Temper: HO, H111,H12, H14, H24,H 32, H112, T4, T6, T5,T651

Surface:Mill/Emboss/Diamond/2bar/3bars/Bright

Thickness: 0.2mm to 300mm

Width: 30mm to 2300mm

Length:1000mm to 10000mm.

Aluminum stair tread sheet, Aluminum tread Brite plate,Aluminum checker plate manufacturers, Perforated aluminum sheet china,Diamond sheet manufacturers, Aluminum tread plate manufacturers