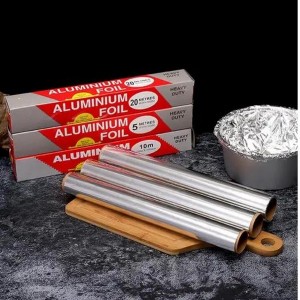

China Disposable Food Grade 8011 Jumbo Barbecue Baking use food packaging Aluminum Foil Paper Manufacturer and Supplier | Ruiyi

Hygienic food grade households aluminum foil Roll or Aluminum foil, also known as aluminium foil, is a tool made of flattened metal aluminum, mainly used for cooking in the kitchen, holding food, food packaging, or making some materials that can be easily cleaned.

Aluminum foil or aluminum roll, also called tin foil, is a paper-thin, shiny sheet of aluminum metal. It’s made by rolling large slabs of aluminum until they are less than 0.2mm thickness. It’s used industrially for various purposes like packing, insulation,transportation and kitchen use or households use.

Aluminium coil is a metal product that is subjected to flying shear after being rolled by a casting and rolling machine and processed by drawing and bending angles.

Aluminum coils are widely used in electronics, packaging, construction, machinery, etc. RAYIWELL MFG / RuiYi Aluminum as one of aluminum coil manufacturers in China, the production technology has caught up with developed countries. According to the different metal elements contained in aluminum coils, aluminum coils can be roughly divided into 9 categories. , which can be divided into 9 series.

Aluminium coil metal are widely used in construction, packaging, air conditioners, refrigerators, solar energy, cosmetics and other industries, and can also be used for anti-corrosion and heat preservation in power plants, chemical and petrochemical plants

Color-coated aluminum (color-coated aluminum coil), as the name implies, is to carry out surface coating and coloring treatment on aluminum plate or (aluminum coil). Usually fluorocarbon color-coated aluminum (color-coated aluminum coil) and polyester color-coated aluminum (color-coated aluminum coil) are widely used in aluminum-plastic panels, aluminum veneers, aluminum honeycomb panels, aluminum ceilings, roof surfaces, scraps, cans and electronics. Its performance is very stable and it is not easy to be corroded. After special treatment, the surface can achieve 30 years of quality assurance. The unit volume weight is the lightest among metal materials. This is a new popular aluminum color coated profile.

Aluminum coils are called aluminum plates or sheets, with a thickness of 0.2 mm to 500 mm, a width of 200 mm, and a length of 16 meters. more and more strips). Aluminum plate refers to a rectangular plate rolled from an aluminum ingot, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate and medium-thick aluminum plate. Aluminum plates are widely used in construction, packaging, air conditioners, refrigerators, solar energy, cosmetics and other industries, and can also be used for anti-corrosion and heat preservation in power plants, chemical and petrochemical plants.

The raw materials of aluminum coils are mainly pure aluminum, hot-rolled aluminum coils or aluminum alloy cast-rolled aluminum coils. These raw materials are put into a cold rolling mill and rolled into thin aluminum coils of different thicknesses and widths, and then the aluminum coils are put into a slitting machine for slitting. The aluminum strips of different widths formed after slitting can play their own roles in actual operation.

There are many classifications of aluminum coils, such as 1050, 1060, 1070, 1100, 3003, 3004, etc. There are two main states of aluminum strip: soft state and hard state. The soft state is represented by the letter O, and the hard state is represented by the letter H. Numbers can be added after the two letters to indicate the hardness or annealing degree of the aluminum coil.