China 6061 T651 aerospace aluminum sheet Manufacturer and Supplier | Ruiyi

China aluminum supplier RAYIWELL MFG / Top Metal Manufacture can supply AMS4027N aircraft standard 6061-T651 aluminum sheet.

The main alloying elements in 6061 aluminum alloy are magnesium and silicon, which have medium strength, good corrosion resistance, weldability, and good oxidation effect.

Magnesium-aluminum 6061-T651 is the main alloy of the 6-series alloy. It is a high-quality aluminum alloy product that has been heat-treated and pre-stretched. Magnesium-aluminum 6061 has excellent processing performance, good corrosion resistance, high toughness and no deformation after processing. It has excellent characteristics such as easy coloring film and excellent oxidation effect.

Main application of 6061-T651: Widely used in various industrial structural parts that require a certain strength and high corrosion resistance, such as manufacturing trucks, tower buildings, ships, trams, and railway vehicles.

Production and management in accordance with international aerospace quality system certifications: AS9100; OHSAS 18001; ISO14001; ISO 9001; NADCAP HT; NADCAP NDT; IATP16949

Production standards: AMS 4027; HP20; HS20; QQ-A-250/11; EN 4213.

6061 T651 is an aluminum alloy commonly used in a variety of applications, including aerospace. To produce 6061 T651 aerospace aluminum sheet, several requirements must be met, including:

Raw material

The aluminum used to produce 6061 T651 aircraft aluminum sheet must meet the appropriate standards and specifications for this alloy. This may include specific chemical composition, purity and other requirements.

Casting

The raw material is melted and cast into large or small plates using processes such as continuous casting or direct chill casting.

Rolling

The billet is then heated and passed through a series of rolling mills to reduce its thickness and shape it into plates. This process may include hot rolling, cold rolling, or both.

Heat treatment

To meet the requirements of T651, the plate is subjected to a heat treatment called solution heat treatment.

Aging

After solution heat treatment, the plate is quenched in water or other cooling medium and then aged in an oven or other heat source. This process strengthens the material and improves its resistance to corrosion and other forms of degradation.

Quality control

Quality control measures must be implemented throughout the production process to ensure that the final product meets the necessary specifications in terms of strength, dimensional accuracy and other performance characteristics.

Overall, the production of 6061 T651 aerospace aluminum sheet requires careful attention to detail and quality assurance at every stage of the manufacturing process. By meeting these requirements, manufacturers can produce high quality sheets for a wide range of applications.

Typical uses of 6061 include aerospace fixtures, electrical fixtures, and communications. It is also widely used in automated mechanical parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC board solder carriers, etc.

The application of 6061-T651 Aluminum sheet is widely used in various industries such as decoration, packaging, construction, transportation, electronics, aviation, aerospace, weapons, etc.

6061 Aluminum materials for aerospace are used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear pillars, as well as rocket forging rings, spacecraft wall panels, etc.

Aluminum materials for transportation are used for car body structural materials of automobiles, subway vehicles, railway passenger cars, high-speed passenger cars, doors and windows, shelves, automotive engine parts, air conditioners, radiators, body panels, wheels and ship materials

All-aluminum cans are mainly used as metal packaging materials in the form of thin plates and foils, and are made into cans, lids, bottles, barrels, and packaging foils. Widely used in the packaging of beverages, food, cosmetics, medicines, cigarettes, industrial products, etc.

Aluminum materials for printing are mainly used to make PS plates. Aluminum-based PS plates are a new type of material in the printing industry and are used for automatic plate making and printing.

Aluminum alloys for architectural decoration are widely used in building structures, doors and windows, suspended ceilings, decorative surfaces, etc. because of their good corrosion resistance, sufficient strength, excellent process performance and welding performance. Such as various building doors and windows, aluminum profiles for curtain walls, aluminum curtain wall panels, profiled panels, checkered panels, color-coated aluminum panels, etc.

Aluminum materials for electronic home appliances are mainly used in various busbars, wiring, conductors, electrical components, refrigerators, air conditioners, cables and other fields. Specifications: round rods, square rods Representative applications include aerospace fixtures, electrical fixtures, and communication fields

| Specifications | |

| Alloy | 6061 |

| Temper | T651 |

| Thickness | 0.2mm-300mm |

| Width | 500~2500mm |

| Length | 500-12000mm |

| Standard | AMS 4027; HP20; HS20; QQ-A-250/11; EN 4213 |

Mother coil: CC or DC

Weight: About 2mt per pallet for general size

MOQ: 5-10ton per size

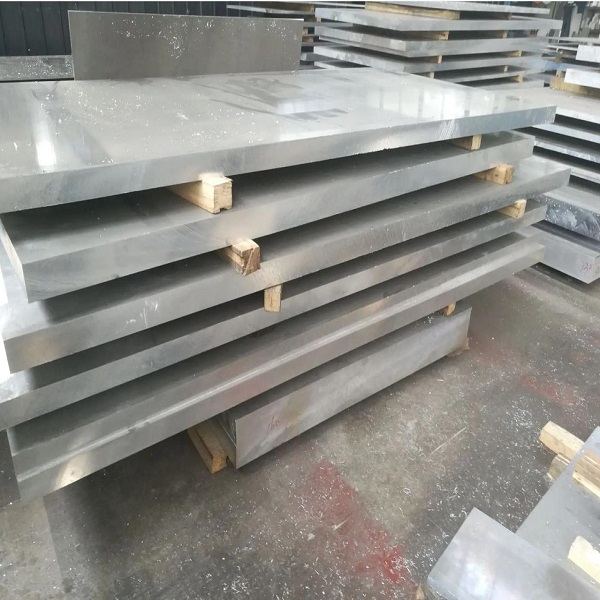

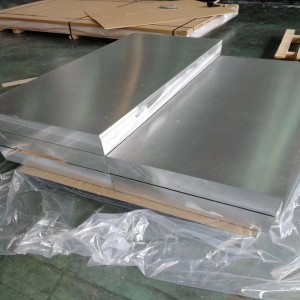

Protection: paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement.

Surface: clean and smooth, no bright speck, corrosion, oil, slotted, etc.

Standard product: GBT3880, JIS4000, EN485, ASTM-B209, EN573, ASTMB221, AMS-QQ-A-200/8, ASMESB221

Delivery time: about 30days after receiving the deposit

Payment: T/T, L/C at sight

Trading terms: FOB, CIF, CFR

6061 T651 aerospace aluminum sheet mechanical properties

| Temper | Thickness (mm) | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation (%) |

| T6 | 0.4-1.5 | ≥290 | ≥240 | ≥6 |

| T6 | 1.5-3 | ≥290 | ≥240 | ≥7 |

| T6 | 3-6 | ≥290 | ≥240 | ≥10 |

| T651 | 6-12.5 | ≥290 | ≥240 | ≥10 |

| T651 | 12.5-25 | ≥290 | ≥240 | ≥8 |

| T651 | 25-50 | ≥290 | ≥240 | ≥7 |

| T651 | 50-100 | ≥290 | ≥240 | ≥5 |

| T651 | 100-150 | ≥290 | ≥240 | ≥5 |

6061 T651 is an aluminum alloy grade typically used in structural applications such as in aerospace, transportation and construction. The following are some of the advantages of using 6061 T651 aerospace aluminum sheet.

High strength

6061 T651 has excellent mechanical properties, including high strength and good fatigue resistance. This makes it a suitable material for load-bearing applications.

Corrosion resistance

Aluminum has a natural ability to resist corrosion and 6061 T651 is no exception. This makes it a popular choice for outdoor or marine applications, where the material may be exposed to moisture or salt water.

Weldability

6061 T651 is a highly weldable material, which makes it easy to join to other components or structures.

Machinability

6061 T651 is also easily machinable, which makes it a popular choice for fabricating parts with complex shapes and contours.

Lightweight

Aluminum is a lightweight material, which makes it an ideal choice for applications where weight is a critical factor.