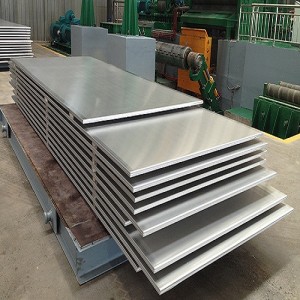

China 5052 aluminum sheet factory aluminum coil supplier Manufacturer and Supplier | Ruiyi

The main difference between 5052 and 6061 aluminum is that 6061 is a heat-treatable alloy and therefore stronger than 5052 aluminums. 6061 also features high resistance to stress combined with good formability and weldability.

Comparing with alloy 3003, In general, 3003 is fairly soft and has good corrosion resistance, good drawing, good workability, moderate strength, and is weldable, while 5052 is stronger and has better corrosion resistance, good drawing, good formability, higher strength, and also is weldable.

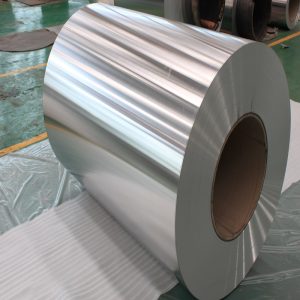

When annealed, aluminium alloy 5052 is stronger than 1100 and 3003 alloys. It is one of the higher strength, non-heat-treatable alloys and has good workability. It also has very good corrosion resistance, especially to salt water

For painting flat sheets, 5052 or 5005 alloy aluminum is recommended if material is to be fabricated after finishing. When specifying a custom paint, it is vital that a non-exposed surface is clearly identified

5052 aluminum is frequently used for general sheet metal work, heat exchangers, flooring panels, rivets and wires, chemical drums and other equipment, pressure vessels, treadplate, containers, and more

5052 alloy aluminum offen was used in kitchen cabinets, appliances, fans and fan blades, home freezers, clock plates, fencing, and more.

5052 alloy aluminum has made its way into aircraft, bus, and truck manufacturing, road and name signs, fuel lines and tanks, streetlights, and other hallmarks of the transportation industry