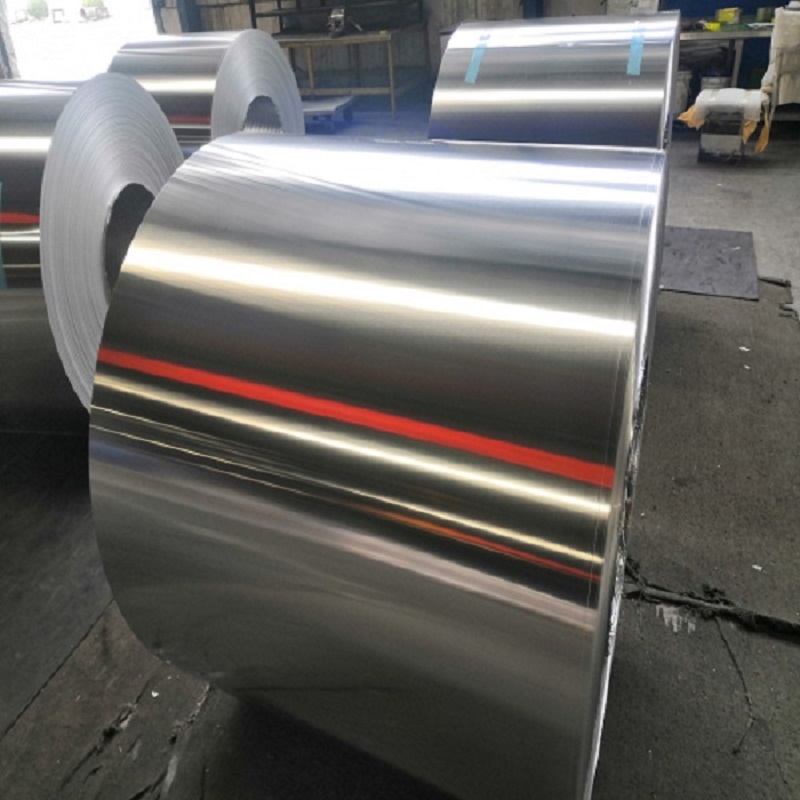

China 3003 aluminium coil Manufacturer and Supplier | Ruiyi

Aluminium is a versatile material widely used in various industries due to its excellent properties, including its lightweight, corrosion resistance, and high thermal conductivity. Among the different aluminum grades available, grade 3003 is a popular choice for coil applications. In this article, we will explore the properties, applications, and advantages of aluminium coil grade 3003.

Properties of Aluminum Coil Grade 3003:

Aluminum coil grade 3003 belongs to the 3xxx series aluminum alloy, which is composed of aluminum, manganese, and a small percentage of copper. The addition of manganese enhances the strength and corrosion resistance of the alloy, making it suitable for a wide range of applications. Some key properties of aluminum coil grade 3003 include:

1. High Corrosion Resistance: Grade 3003 exhibits excellent resistance to atmospheric corrosion, making it ideal for outdoor applications.

2. Good Formability: The alloy has good formability, allowing it to be easily shaped into various forms such as coils, sheets, and plates.

3. Weldability: Aluminum coil grade 3003 can be easily welded using common methods such as MIG and TIG welding, making it suitable for fabrication processes.

4. Excellent Thermal Conductivity: The alloy offers high thermal conductivity, allowing for efficient heat transfer in heat exchangers and other thermal applications.

Applications of Aluminium Coil Grade 3003:

Due to its favorable properties, aluminum coil grade 3003 finds applications in various industries. Some common applications include:

1. Roofing and Cladding: The corrosion resistance and formability of grade 3003 make it an excellent choice for roofing and cladding applications, especially in areas prone to harsh weather conditions.

2. Heat Exchangers: The high thermal conductivity of grade 3003 makes it suitable for use in heat exchangers, where efficient heat transfer is crucial.

3. Food and Beverage Packaging: The alloy’s corrosion resistance and non-toxic nature make it a preferred choice for manufacturing food and beverage packaging materials such as cans, lids, and foils.

4. HVAC Systems: Aluminum coil grade 3003 is widely used in HVAC systems for its corrosion resistance and formability, making it suitable for manufacturing air conditioning coils and fins.

Advantages of Aluminum Coil Grade 3003:

Choosing aluminum coil grade 3003 offers several advantages, including:

1. Lightweight: Aluminum is a lightweight material, making it easier to handle and transport compared to other metals.

2. Cost-effective: Aluminum coil grade 3003 is relatively affordable compared to other aluminum grades, making it a cost-effective choice for various applications.

3. Environmental Sustainability: Aluminum is a highly recyclable material, making it an environmentally friendly option. Grade 3003 can be recycled repeatedly without losing its properties.

4. Versatility: Aluminum coil grade 3003 can be easily formed, fabricated, and finished, allowing for customization and versatility in design and application.

Conclusion:

Aluminum coil grade 3003 offers a range of desirable properties, making it a popular choice for various applications. Its corrosion resistance, formability, and thermal conductivity make it suitable for roofing, cladding, heat exchangers, packaging, and HVAC systems. With its lightweight nature, cost-effectiveness, and recyclability, grade 3003 provides an excellent solution for industries seeking durable and sustainable materials.

The aluminum alloys we usually refer to are generally aluminum-magnesium-silicon alloys, that is, 6-series aluminum alloys. This type of aluminum alloy profile has a certain hardness, can meet the general load-bearing requirements, and has strong corrosion resistance, and has the widest application range. But aluminum alloys are by no means limited to this category. According to the different components of aluminum alloys in the world, aluminum alloys are classified, that is, they are divided into different grades

1 series aluminum alloy is pure aluminum series, the aluminum content reaches 99.9%, such as 1020, 1060, 1100, 1150, 1170, 1175, 1180, 1185, 1193, 1199, 1200, 1230, 1260, 1345, 1350, 1370, 1385, 1435···

The 2-series aluminum alloys are copper-aluminum alloys. Aluminum alloys with copper as the main alloying element also add magnesium, lead and bismuth to improve cutting performance. 2-series aluminum alloys include 2A12, 2011, 2014, 2017, 2021, 2024, 2034, 2117, 2124, 2218, 2219, 2224, 2319, 2324, 2519, 2618…

The 3-series aluminum alloy is an aluminum-manganese alloy, with manganese as the main alloying element. No heat treatment strengthening, good corrosion resistance, good welding performance, good plasticity, close to super aluminum alloy. 3 series aluminum alloy grades are 3002, 3003, 3009, 3010, 3011, 3012, 3015, 3103, 3104, 3A12, 3A21, 3203, 3303

The 4-series aluminum alloy is an aluminum-silicon alloy, with silicon as the main alloying element. Some can be strengthened by heat treatment, and this type of aluminum alloy is not commonly used. The main grades are 4004, 4032, 4047, 4104

The 5-series aluminum alloy is an aluminum-magnesium alloy, and magnesium is the main alloying element. This kind of aluminum alloy has good corrosion resistance, good welding performance and good fatigue strength. But it cannot be strengthened by heat treatment, and the strength can only be improved by cold working. Grades are 5005, 5010, 5013, 5014, 5016, 5040, 5042, 5043, 5049, 5050, 5051, 5052, 5056, 5082, 5083, 5086, 5150, 5151, 5154, 5182, 5183, 5205, 5250, 525 1. 5252, 5254, 5280, 5283, 5351, 5356, 5357, 5451, 5454, 5456, 5457, 5552, 5652, 5654, 5657, 5754, 5854…

6 series aluminum alloy, the most widely used aluminum alloy. Magnesium and silicon are the main alloying elements. It has medium strength, good corrosion resistance, good welding performance, easy extrusion and oxidation coloring. Therefore, most of the aluminum alloy profiles are 6 series aluminum alloys. There are 6008, 6011, 6012, 6015, 6053, 6060, 6061, 6063, 6066, 6070, 6082, 6101, 6103, 6105, 6110, 6111, 6151, 6162, 6181, 6205, 6253, 6261, 6262, 6351, 6463 , 6763, 6863, 6951·

7 series aluminum alloy, with zinc as the main alloying element, but a small amount of copper and magnesium are also added at the same time. The superhard aluminum alloy belongs to the 7 series, which contains zinc, lead, magnesium, and copper, and its hardness is close to that of steel. The extrusion cost of 7-series aluminum alloy profiles is relatively high, and the welding performance is good. Commonly used in the aerospace field. ) Seven-series aluminum alloy grades are 7001, 7003, 7004, 7005, 7008, 7009, 7010, 7011, 7012, 7013, 7014, 7015, 7017, 7019, 7020, 7021, 7022, 7023, 7024, 7026, 7027, 7028 , 7029, 7030, 7039, 7046, 7049, 7050, 7051, 7060, 7072, 7075, 7075-T651, 7076, 7079, 7108, 7109, 7116, 7146, 7149, 7150, 7175, 7179, 7229, 7278, 7472 , 7475… Among them, 7005 and 7075 are the highest grades in the 7 series.