China Commercial use hot rolled steel plate Hot rolled Pickled steel coils Manufacturer and Supplier | Ruiyi

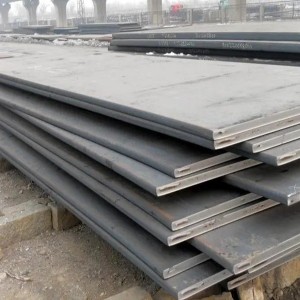

Hot-rolled steel is a steel that has been heated and rolled at high temperature. Its strength is not very high, but it is sufficient for our use. Its plasticity and weldability are better, so we often use it; cold-rolled steel is ordinary hot-rolled steel. The steel that has been drawn by force and exceeds the strain hardening stage has high strength, but poor toughness and weldability, and is relatively hard and brittle. Hot rolling is processed at high temperature. Hot rolling means that the material needs to be heated during or before rolling steel. Generally, it is heated above the recrystallization temperature before rolling.

1. The cold-rolled formed steel allows local buckling of the section, so that the bearing capacity after buckling of the bar can be fully utilized; while the hot-rolled section does not allow local buckling of the section.

2. The reasons for the residual stress of hot-rolled steel and cold-rolled steel are different, so the distribution on the cross-section is also very different. The residual stress distribution on the cold-formed thin-walled steel section is curved, while the residual stress distribution on the hot-rolled or welded steel section is film-shaped.

3. The free torsional stiffness of hot-rolled steel is higher than that of cold-rolled steel, so the torsional performance of hot-rolled steel is better than that of cold-rolled steel

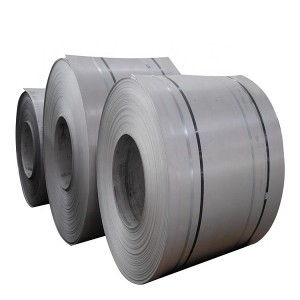

Main grades for domestic market: Q195、Q215B、Q235B, and for international market:: S235JR、SS400、A36、S275JR、S275J0、SS490、SPHT1、SPHT2、SPHC、SPHD、SPHE. The product is widely used in welded pipe, steel structure, shelf, hardware, machinery, vehicles and other industries. Size range: (1.5-25.4)*(940-2000)mm

Hot-rolled products have excellent properties such as high strength, good toughness, easy processing and good weldability, so they are widely used in manufacturing industries such as ships, automobiles, bridges, construction, machinery, and pressure vessels.

Advantages and disadvantages of hot rolling:

Advantages: It can destroy the casting structure of the steel ingot, refine the grains of the steel, and eliminate the defects of the microstructure, so that the steel structure is dense and the mechanical properties are improved. This improvement is mainly reflected in the rolling direction, so that the steel is no longer isotropic to a certain extent; the bubbles, cracks and looseness formed during pouring can also be welded under high temperature and pressure.

shortcoming:

1. After hot rolling, the non-metallic inclusions (mainly sulfides and oxides, as well as silicates) inside the steel are pressed into thin sheets, and delamination (interlayer) occurs. Delamination greatly deteriorates the properties of the steel in tension through the thickness, and there is a possibility of interlaminar tearing as the weld shrinks. The local strain induced by the shrinkage of the weld often reaches several times the strain at the yield point, which is much larger than the strain caused by the load;

2. Residual stress caused by uneven cooling. Residual stress is the internal self-equilibrium stress without external force. Hot-rolled steel sections of various sections have this kind of residual stress. Generally, the larger the section size of the section steel, the greater the residual stress. Although the residual stress is self-equilibrium, it still has a certain influence on the performance of the steel member under the action of external force. For example, it may have adverse effects on deformation, stability, fatigue resistance, etc.

Advantages and disadvantages of cold rolling:

Advantages: fast forming speed, high output, and no damage to the coating, can be made into a variety of cross-sectional forms to meet the needs of the use conditions; cold rolling can cause a large plastic deformation of the steel, thereby improving the yield of the steel point.

shortcoming:

1. Although there is no thermal plastic compression during the forming process, there are still residual stresses in the section, which will inevitably affect the overall and local buckling characteristics of the steel;

2. The style of cold-rolled section steel is generally an open section, so that the free torsional stiffness of the section is low. It is easy to twist when it is bent, and it is easy to buckle when it is compressed, and its torsional performance is poor;

3. The wall thickness of the cold-rolled formed steel is small, and there is no thickening at the corner where the plates are connected, and the ability to withstand local concentrated loads is weak.

The main steel grade includes SAPH370、SAPH400、SAPH440、QStE340TM、QStE420TM、330CL、380CL、510L、610L. Now automobile steel products refer to Automobile wheel steel, automobile girder steel, automobile structure steel, etc. It has the advantage of high strength, flexibility and plasticity,high fatigue resistance, wear resistance, and hot cracking resistance. Gauge covers(2.5-14)*(1010-2000)mm

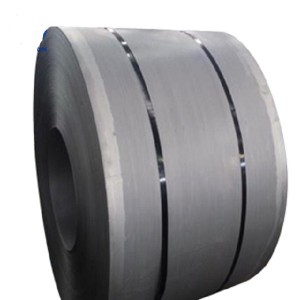

Pickling plate (Pickling plate, pickled steel board) is made of high-quality hot-rolled sheet as raw material. After the pickling unit removes the oxide layer, trims the edge, and finishes, the surface quality and use requirements (mainly cold-formed or stamped performance) The intermediate product between hot-rolled sheet and cold-rolled sheet is an ideal substitute product for some hot-rolled sheet and cold-rolled sheet. Compared with hot-rolled sheets, the advantages of pickled sheets are mainly: 1) The surface quality is good. Since the hot-rolled pickled sheets remove the surface oxide scale, the surface quality of the steel is improved, and it is convenient for welding, oiling and painting. 2) The dimensional accuracy is high. After leveling, the plate shape can be changed to a certain extent, thereby reducing the deviation of unevenness. 3) Improve the surface finish and enhance the appearance effect. 4) It can reduce the environmental pollution caused by the user’s scattered pickling.

The main processes of hot-rolled pickled plates include laser welding, position stretching and straightening, turbulent pickling, online leveling, edge trimming, and online oiling, etc.

Baosteel pickling specifications are generally 1.0-6.1*800-1650mm. Products include low-, medium-, and high-strength grades of steel for stamping, steel for automotive structures, etc., and are mainly delivered in the form of steel coils. Technological features Use hydrochloric acid to remove the iron oxide scale on the hot-rolled steel plate to obtain a beautiful and smooth surface.

1. The main uses of hot-rolled pickling in the automotive industry are as follows: automotive chassis systems, including girders and sub-beams. Wheels, including rims, spokes, etc. Cab panel. The compartment plate is mainly the compartment floor of various trucks. Other stamping parts, including anti-collision bumpers, brake housings and other small parts inside the car.

2. The machinery industry (excluding automobiles) mainly includes textile machinery, mining machinery, fans and some general machinery.

3. Light industrial appliances, mainly used to manufacture compressor casings, brackets, water heater inner tanks, etc. Chemical barrels.

4. Other bicycle parts, various welded pipes, electrical cabinets, highway guardrails, supermarket shelves, warehouse shelves, fences, iron ladders and stamping parts of various shapes

HOT ROLLED PICKLED COIL

| USAGE | QUALITY STANDARD | GRADE | |||

| Suitable for Cold Rolling and Galvanizing | DIN 1614-Part 1 | St 22 | |||

| St 22-(Low Cupper) | |||||

| RRSt 23 | |||||

| St 24 | |||||

| DIN EN 10111-2008 | DD11-(Low Cupper) | ||||

| DD11 | |||||

| DD11-(High Tensile) | |||||

| Cold Drawing | DIN EN 10111-2008 | DD12 | |||

| Deep Drawing | DIN EN 10111-2008 | DD13 | |||

| General construction Steel suitable for Galvanizing | DIN EN 10025 Part 2 -2004 | S235JR | |||

| S235JR (Cu+Cr+Ni≤0.35) | |||||

| S235J0 (Cu+Cr+Ni≤0.35) | |||||

| S235J0 (Cu+Cr+Ni≤0.35) | |||||

| S235J0 | |||||

| S235J2 | |||||

| S275JR | |||||

| S275J0 | |||||

| S275J2 | |||||

| Carbon Steel | SAE J403-2001 | SAE 1006 | |||

| SAE 1008 | |||||

| SAE 1008 Modi ed | |||||

| SAE 1008 Low Cu | |||||

| SAE 1010 | |||||

| SAE 1010 – Modi ed | |||||

| SAE 1010 Low Cu | |||||

| SAE 1012 | |||||

| SAE 1015 | |||||

| SAE 1015 Low Cu | |||||

| SAE 1018 | |||||

| SAE 1018 – Modi ed | |||||

| SAE 1020 | |||||

| SAE 1022 Modi ed | |||||

| SAE 1022 | |||||

| SAE 1025 | |||||

| SAE 1030 | |||||

| SAE 1040 | |||||

| SAE 1045 | |||||

| LPG Pressure Vessel Steel | DIN EN 10120-2008 | P245NB | |||

| P265NB | |||||

| P310NB | |||||

| P355NB | |||||

| Structural Steel | JIS G 3101: 2004 | SS400 |