China Aluminum Honeycomb Sheet Manufacturer and Supplier | Ruiyi

Product Description

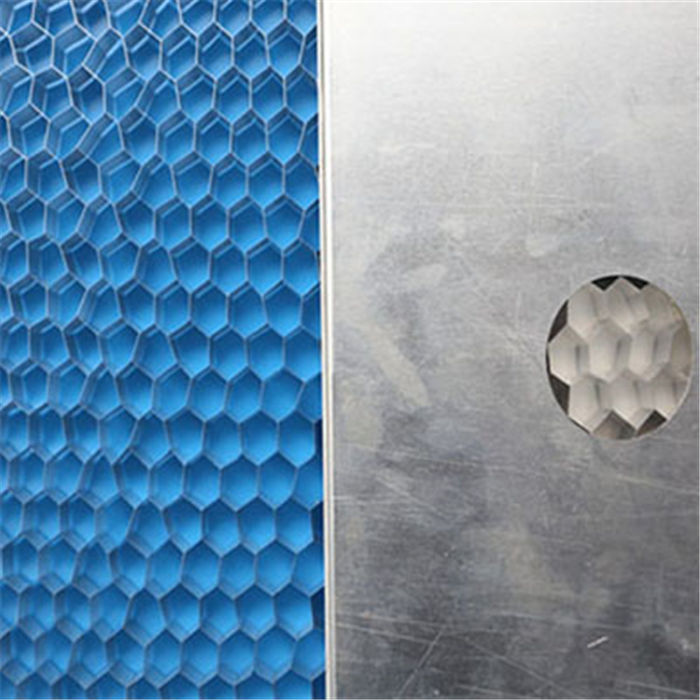

Aluminum honeycomb sheet is another popular composite aluminum sheet. The aluminum honeycomb board is a aluminum composite sheet with aluminum honeycomb core. The material of aluminum honeycomb panels is mainly aluminum alloy 3003 or 5000 series aluminum.

Aluminum honeycomb sheet is another popular composite aluminum sheet. The aluminum honeycomb board is a aluminum composite sheet with aluminum honeycomb core. The material of aluminum honeycomb panels is mainly aluminum alloy 3003 or 5000 series aluminum.

Aluminum honeycomb density is lower. So aluminum honeycomb panel is light weight and high strength. Lightweight honeycomb panels can reduce the load of the building. Meanwhile, the surface of aluminium honeycomb panel is smooth and its maximum layout size can reach to 1550*5000 mm.

As a kind of aluminum cladding panel, aluminum honeycomb sandwich panel has sound insulation and heat insulation functions. So, aluminium honeycomb composite panel is an ideal material for ceiling. And the design of these composite ceiling panels are varied, which can meet the different needs of customers.

Application

Honeycomb aluminum panels can be applied to various industries.Generally speaking, aluminum honeycomb sandwich panel applications are mainly include:

Exterior aluminium wall cladding.

Aluminum wall panels indoor.

Aircraft honeycomb panels.

Aluminum honeycomb sandwich panel billboard.

Buses, trains, subways and rail vehicles.

Commercial transporter and container car body.

Honeycomb aluminum panel partition.

Aluminum honeycomb panel is suitable for civil construction, vehicle and ship decoration, etc. It is the application of aviation and aerospace materials in the field of civil construction. The entire processing process is completed in a modern factory, using hot press forming technology. Due to the high heat transfer value between the aluminum skin and the honeycomb, the thermal expansion and contraction of the inner and outer aluminum skins are synchronized; the honeycomb aluminum skin has small holes, so that the gas in the plate can be free. Flow; the slidable mounting buckle system will not cause structural deformation during thermal expansion and contraction.