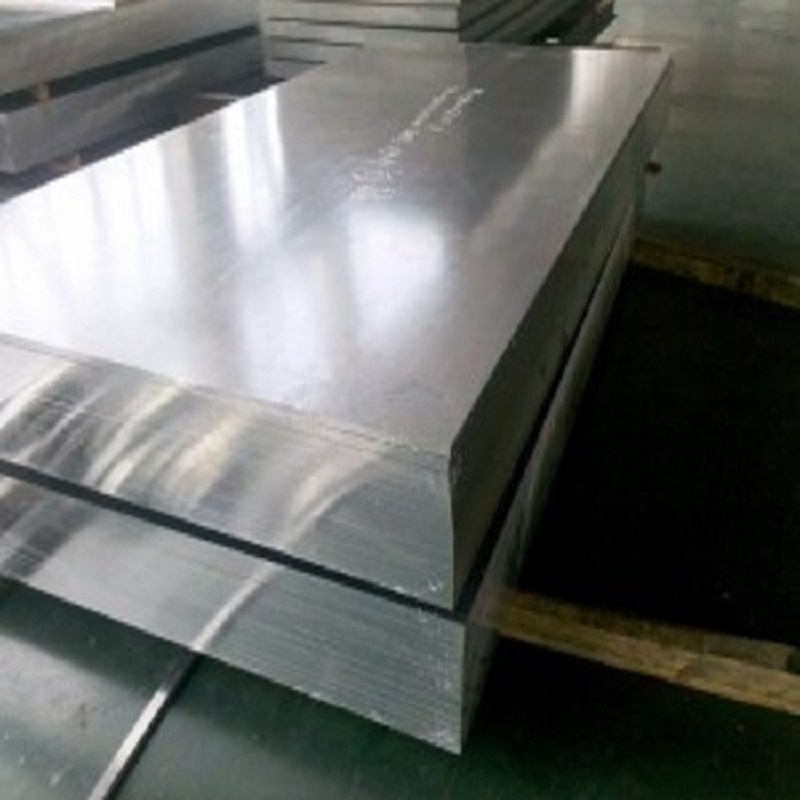

China 7475 T6 Aerospace aluminum plate sheet Manufacturer and Supplier | Ruiyi

7475 aluminum alloy is a wrought alloy with high zinc weight percentage. It also contains magnesium, silicon and chromium.

7475 alloy can not be welded. It has more spring back because of its strength. It has high machinability.

7475 aluminium sheet typically offers a 40% increase in toughness when compared to 7075 aluminium. While the performance characteristics of 7075 are similar, 7475 aluminium sheet offers improved fatigue and corrosion resistance performance comparable with and often better than other high strength aluminium grades. 7475 aluminium sheet is suitable for applications where considerations include high mechanical strength, improved fracture toughness, and fatigue crack propagation are of greater importance

7475 Aluminum Sheet Properties

1. The unique grain refinement process guarantees that all the aviation aluminum alloy series can pass the ultrasonic inspection process. It has no porosity, cracks, bubbles and impurities.

2. Internal stress: The perfect pre-stretching process completely eliminates internal stress, and it does not warp, crack or deform during processing.

3. Tolerance accuracy: It complies with the American Society for Testing and Materials (ASTM) and Aerospace Material Specifications (AMS).

4. Processing performance: The deviation of chemical composition, strength and hardness is minimized, therefore, it has good processing performance

5. Uniformity: RuiYi Aluminum has heat treatment technology. When the 7475 aluminum sheet is below 300mm thickness, the strength and hardness can be kept consistent.

6. Stability: All production processes are controlled by computer, with few human deviations, and the same performance can be guaranteed for different batches of production.

7. Anodizing effect: Its anodizing effect is uniform and shiny, and there is no surface defects.

8. Corrosion resistance: It has excellent stress corrosion resistance and will not cause dents or blacken in long-term use under various media (such as water vapor, weak acid and weak alkali, etc.)

9. High temperature resistance:It will produce no permanent deformation during operation at 400°C.

10. Bending performance: All the plates have passed the semi-conductive bending test, and no cracking will occur when bent 180 degrees.

Chemical Composition

| ALLOY | SI | FE | CU | MN | MG | CR | ZN | ZR | TI | STANDARD |

| 7475 | 0.10 | 0.12 | 1.2-1.9 | 0.06 | 1.9-2.6 | 0.18-0.25 | 5.2-6.2 | 0.06 | 0.05 | GB/EN/AMS |

| ALLOY | TEMPER | THICKNESS(MM) | WIDTH(MM) |

| 7475 | O | 0.5-4.0 | 1000-2650 |

| ALLOY | TEMPER | THICKNESS(MM) | TENSILE STRENGTH(MM)

RM(MPA) |

YIELD STRENGTH

RP0.2(MPA) |

BREAKING ELONGATION

A50% |

STANDARD |

| 7475 | O | 0.5-4.0 | 185-205 | 90-110 | 18-22 | GB/EN/AMS |